Automatic Multi-Lane Milk Powder Stick Packaging Machine Boxing Production Line

Model: LD280BK

Application:

It is suitable for the automatic filling of various powder products, such as milk powder, coffee powder, protein powder, nutritional powder, medicine powder, chemical powder, meal replacement powder, etc.

Application:

It is suitable for the automatic filling of various powder products, such as milk powder, coffee powder, protein powder, nutritional powder, medicine powder, chemical powder, meal replacement powder, etc.

Packaging Line Composition:

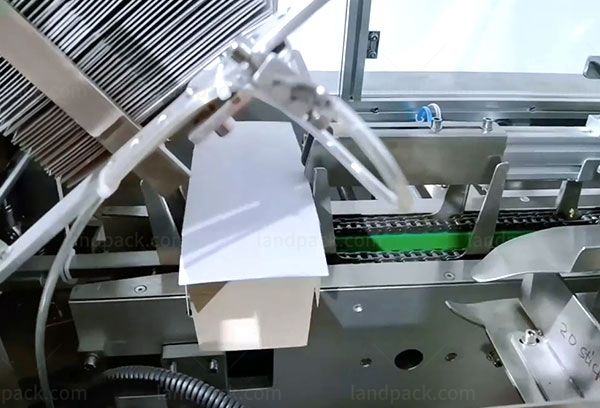

This packaging and boxing system consists of LD-280BK Multi-lane stick pack fine granule packaging machine, a sorting bag equipment and LD200ZH boxing machine. It can realize stick packed packaging into a box.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

| MULTI-LANE STICK PACK POWDER PACKAGING MACHINE | |

Model | LD280BK |

Lane number | 2-6 Lanes |

Filling Method | 1. Volumetric cup; 2. Weigher; |

Capacity | Max.50 cycles/min |

Sachet size | L: 50-180mm; W: 17-65mm |

Film width & Thickness | Max.280mm, 0.07-0.10mm |

Sealing type | Back sealing/ Stick bag |

Cutting type | 1.Straight cutting; 2.Zig zag cutting; 3.Round cutting; 4.Die-cut |

Air & Power | 0.8Mpa, 0.8m³/min, 3.5kw |

Dimension & weight | 1385*918*2005mm;350kg |

| BOXING MACHINE | |

Model | LD200ZH |

Paper type | 250-400g/²(Boxes need come with pre-fold over) |

Capacity | 30-60 boxes/min |

Box type | Gusseted tongue type; Glue spray type |

Count way | Fixed number type; Numerable type; Manipulator counting |

Boxing way | Orderly type; Unorderly type |

Air & Power | 0.5-0.8Mpa, 0.3m³/min, 220V, 50/60HZ, 2.0KW |

Workflow | Box open - Bag packing - Check weigher - Counting - Boxing- Fold ears - Fold page - Gusseted tongue/Glue spray - Finish |

1. Customizable Modular Design: The machine’s module structure allows customization to meet specific customer needs.

2. Efficient Film Usage and Material Savings: By minimizing film waste, this equipment optimizes material usage during the packaging process.

3. Humanized Installation and Maintenance: The equipment is easy to install, disassemble, and maintain, thanks to its thoughtful design.

4. Automatic Alarm System: The machine features an automatic alarm system, enhancing safety and preventing material wastage.

5. Easy Mobility with Casters: The equipment is equipped with casters, making it easy to handle and move.

6. Stainless Steel Contact Surfaces: The parts of the machine that come into contact with the product are made of stainless steel, meeting the requirements for pharmaceutical and food production.

7. Hidden Heat and Moving Parts: The heat-generating components and moving parts are discreetly housed within a protective cover, ensuring safety and efficient operation.

8. Automated Multifunctionality: This machine seamlessly performs tasks such as measuring, bag making, sealing, cutting, counting, and finishing product conveyors.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail