Automatic Double Line Nuts Peanuts Bottles Weighing Rotary Filling Machine With Metal Detector

Model : LD-LP800N

Application :

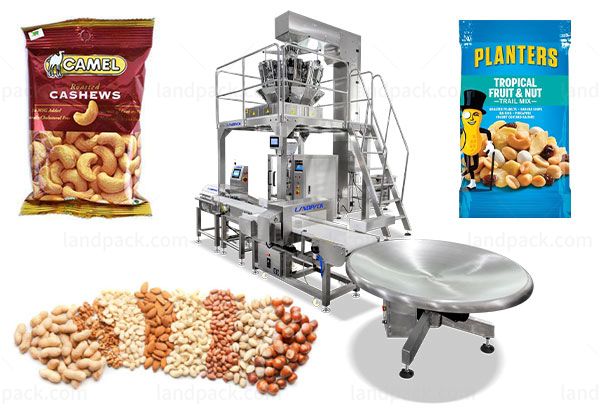

This machine is designed for the automatic bottling and canning of a wide range of granular products. It effectively handles items such as nuts, peanuts, beans, cereals, rice, granola, snack mixes candy, sunflower seeds, potato chips, popcorn, almonds, dried fruits, vegetable salads, frozen foods, jellies, biscuits, chocolates, filberts, corn, and pet food.

Application:

This machine is designed for the automatic bottling and canning of a wide range of granular products, making it an ideal solution for various food packaging needs across different industries.

Examples:

Nuts, peanuts, beans, cereals, rice, granola, snack mixes candy, sunflower seeds, potato chips, popcorn, almonds, dried fruits, vegetable salads, frozen foods, jellies, biscuits, chocolates, filberts, corn, and pet food.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

| Automatic Bottle feeder | |||||

| Machine Model | LD-LP800N | ||||

| Power Supply | 220V/110V, 50-60Hz, 200W | ||||

| Turntable Diameter | 800mm | ||||

| Suitable Bottle Diameter | 40-130mm | ||||

| Suitable Bottle Height | 30-200mm | ||||

| Working Speed | 40-60 bottles/min(depending on bottle size) | ||||

| Package Size | 1230*1010*1260mm | ||||

| Gross Weight | 141kg | ||||

| Multi- heads granules weighing double heads rotary filling machine | |||||

| Model | LD-GZJ200M-R(double turntable filling) | LD-GZJ100M-R(Single turntable filling) | |||

| Material | 304# Stainless steel | ||||

| Applicable heigh | 50-200mm (customized according to Bottle size) | ||||

| Filling speed | 30-50 cans per minute | 10-20 cans per minute | |||

| Air source | 0.6-0.8Mpa | 0.3-0.5Mpa | |||

| Voltage | 220V, 50HZ | ||||

| Power | 2.5KW | 1.5KW | |||

| N.W./G.W. | 200/320KGS | 100/220KGS | |||

| Size | 2000*1000*1400mm | 2000*500*1400mm | |||

| Weight detector | |||||

| Model | LD10 | LD100 | LD201 | LD401 | LD1000 |

| Weight Range | 10-99g | 100-200g | 201-400g | 401-999g | 1000-10000g |

| Rate | 65bags/min | 60bags/min | 50bags/min | 45bags/min | 40bags/min |

| Precision | ±0.5g | ±1g | |||

| Minimum scale | 0.1g | ||||

| Predesign pattern | 10kinds | ||||

| Size | 1050*681*1260mm | ||||

| Voltage | 220V | ||||

| Power | 300W | ||||

| High speed capping machine | |||||

| Model | LFX-GS-150(Eight wheel capping) | LFX-GS-250(Six wheel capping) | |||

| Capacity | 40-100Bottles/min | 30-80Bottles/min | |||

| Bottle cap diameter | Φ18mm-Φ80mm(Could be customized) | Φ18mm-Φ80mm(Could be customized) | |||

| Bottle diameter | Φ35mm-Φ140mm(Could be customized) | Φ35mm-Φ140mm(Could be customized) | |||

| Bottle sealing height | 38mm-300mm(Could be customized) | 38mm-300mm(Could be customized) | |||

| Power | 2KW | 1.5KW | |||

| Voltage | 220V, 50HZ | ||||

| Air pressure | 0.6-0.8Mpa | 0.5-0.7Mpa | |||

| Weight | 350kg | 300kg | |||

| Dimensions | H3120*W1544*L2122 | H3100*W1244*L2122 | |||

| Aluminum foil sealing machine | |||||

| Model | LD-ZS(Double Heads Aluminum Foil Sealing) | LF-LB-2000(Single Heads Aluminum Foil Sealing) | |||

| Applicable bottle diameter | Φ10-200mm(Could be customized) | Φ10-200mm(Could be customized) | |||

| Applicable bottle height | H:40-300mm(Could be customized) | H:40-300mm(Could be customized) | |||

| Speed | 0-30 bottles/min | 0-10 bottles/min | |||

| Bottle material | Glass, ceramics, plastics, metals | ||||

| Voltage | 220V,50HZ | ||||

| Power | 1500W | 1200W | |||

| Dimension | 1500*800*1750mm | 1200*600*1550mm | |||

| Automatic labeling machine | |||||

| Model | LFT-SM-200C(double heads labeling) | LFT-SM-100C(Single heads labeling) | |||

| Labeling speed | 10-40Bottles/min | 5-20Bottles/min | |||

| Labeling accuracy | ±1mm | ||||

| Label maximum width | 200mm(Could be customized) | 150mm(Could be customized) | |||

| The size of the object being attached | Height≤400mm; Thickness≤100mm(Could be customized) | ||||

| Label ID | Φ76.2mm | Φ25.4mm | |||

| Label OD | MaxΦ330mm | MaxΦ230mm | |||

| Voltage | 220V, 50HZ | ||||

| Power | 3.5KW | 2.5KW | |||

| Weight | 500kg | ||||

| Dimension | L3002*W1478*H1810mm | L2950*W1400*H1810mm | |||

1. High-Speed Double Rotary Filling Machine: Engineered for rapid filling processes, this machine optimizes production efficiency for high-output operations.

2. Integrated Metal Detection System: Enhances food safety by identifying metal contaminants, ensuring compliance with industry standards and suitability for food packaging.

3. Nitrogen Flushing Capability: Incorporates a nitrogen injection device that helps prolong the shelf life of food products by minimizing oxygen exposure within the packaging.

4. Adjustable Filling Volume: Features customizable settings that allow for precise adjustments in filling volume, accommodating various product specifications.

5. User-Friendly Interface: Equipped with an intuitive control panel that simplifies operation and monitoring, enhancing ease of use for operators in busy production environments.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail