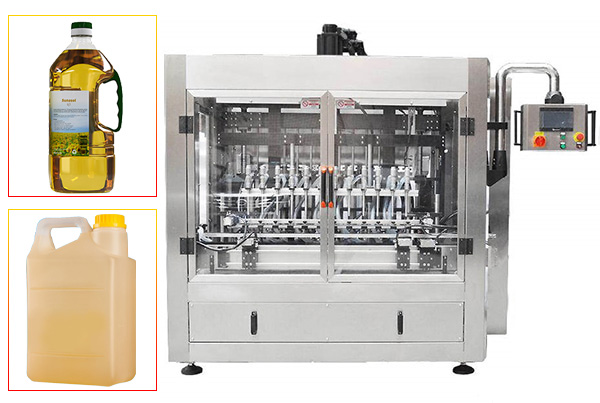

Automatic Viscous Liquid Piston Filling Machine

Model: LF-LZ-12

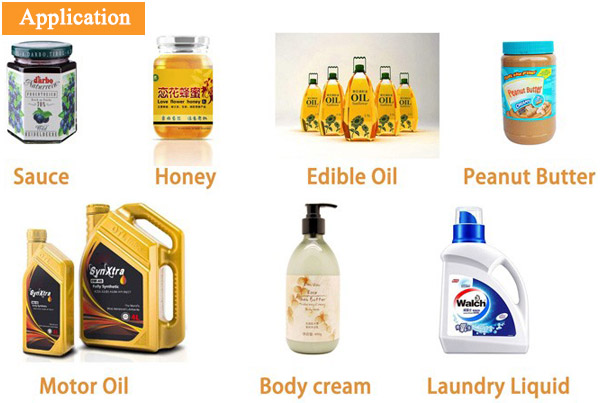

Application:

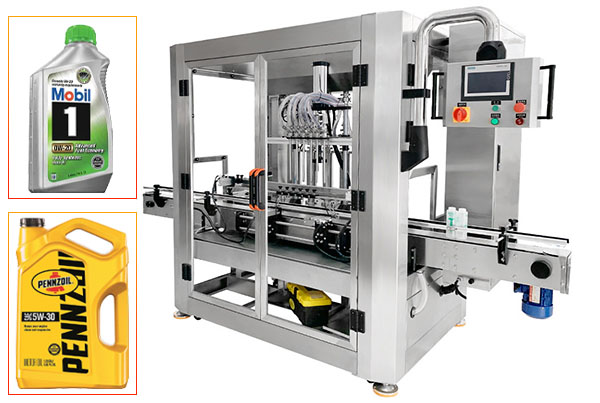

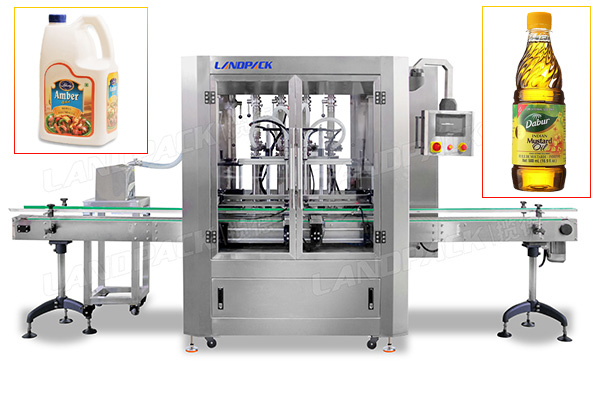

Automatic servo motor bottle filling machine from Landpack can fill up to 16 containers at the same time, Widely used in filling various oils and viscous liquids, such as edible oil, paint, lubricating oil, essential oil, mustard oil, honey, cream, paste, sauce, daily chemicals, and other liquid products.

Advantages:

The filling system is driven by a servo motor which assures high filling accuracy. It is controlled by the PLC, human interface, and easy operation.

Application:

Automatic servo motor bottle filling machine from Landpack can fill up to 16 containers at the same time, Widely used in filling various oils and viscous liquids, such as edible oil, paint, lubricating oil, essential oil, mustard oil, honey, cream, paste, sauce, daily chemicals, and other liquid products.

Packaging Type: Barrel, Bottles, Cans, Capsule, Cartons, Stand-up Pouch

Packaging Material: Glass, Metal, Paper, Plastic, Wood, Other

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

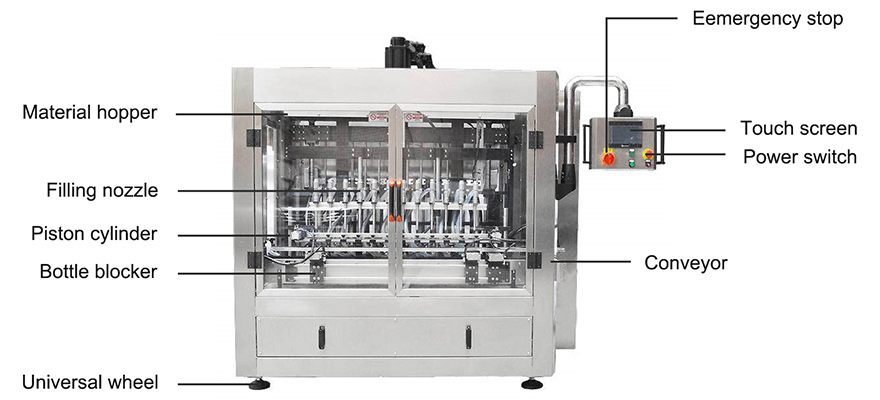

Main structure of automatic piston filler

20L to 200L Top hopper for option, double Jacket hopper with heating and mixing system for option;

Main body of the machine is made of 304SS;

Filling nozzles, filling nozzles are specially designed for anti-drop sauce filling;

Filling nozzles moving up and down by air cylinder, and servo motor moving up and down for option;

PLC control system, and HMI operation;

Specially made horse and valve for honey, with CIP system connection;

Machine Parameters:

Model | LF-LZ-12 |

Filling head | 1/2/4/6/8/10/12(Customizable) |

Filling volume | 100-1000ml,500-5000ml(Customizable) |

Filling speed | 500-5000 bottles per hour |

Voltage | 220V,50-60HZ |

Powder | 2.5KW |

Machine dimension | 2000*900*2100mm |

Machine weight | 550KG |

1. Simple structure in linear type, easy to install and maintain.

2. Piston filling method, accurate and stable, suitable for thick material.

3. The filling range and speed can be designed according to user needs to design different filling head numbers.

4. Adopting advanced world-famous brand components in pneumatic parts, electric parts, and operation parts.WEINVIEW touchscreen, MITSUBISHI PLC, CHNT switch, etc.

5. The whole machine is made of SS304 material, and can meet the requirement of GMP.

6. Can be used for filling containers of different capacities and shapes without the need for additional replacement parts.

7. It can be used alone or connected to production lines, and can be combined with a capping machine, labeling machine, date printer, etc.

8. Easy to clean, all material contact parts can be quickly disassembled and cleaned.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

After receiving your inquiry, We will send you the quotation as soon as possible.