Automatic Multilane Olive Oil Sachet Counting Into Pouch Packing Machine Line

Application:

Widely applied for food, medicine, and chemical liquid products such as olive oil, mouthwash, ketchup, flavoring, sauce, juice, popsicles, pasty, shampoo, salad dressing, cream, body wash liquid, etc.

Advantage:

Automatic packaging and sealing without manual intervention, effectively reducing production and management costs.

Application:

Widely applied for food, medicine, and chemical liquid products such as olive oil, mouthwash, ketchup, flavoring, sauce, juice, popsicles, pasty, shampoo, salad dressing, cream, body wash liquid, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

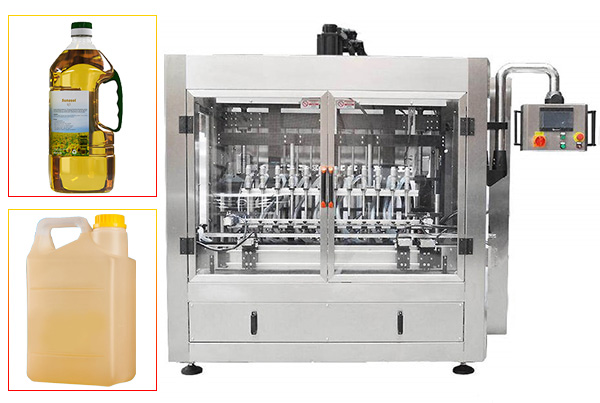

Packaging Sample:

| Multi-Channel Packaging Machines Parameter | |||

| Model | LD-480Y | LD-720Y | LD-960Y |

| Track Number | 4-6 Track | 4-10 Track | 4-12 Track |

| Filling Method | 1. Piston pump; 2. Peristaltic Pump | ||

| Capacity | Max.40 cycles/min | ||

| Sachet Size | L: 45-120mm; W: 35-60mm | L: 45-120mm; W: 35-90mm | L: 45-120mm; W: 35-120mm |

| Film Width & Thickness | Max.480mm; 0.07-0.1mm | Max.720mm; 0.07-0.1mm | Max.960mm; 0.07-0.1mm |

| Sealing Type | 3/4 sides sealing | 3/4 sides sealing | 3/4 sides sealing |

| Cutting Type | 1. Straight Cutting; 2. Zig Zag Cutting; 3. Continuous Cutting | ||

| Air & Power | 0.8 mpa, 0.8m³/min, 2.8kw | 0.8 mpa, 0.8m³/min, 4.1kw | 0.8 mpa, 0.8m³/min, 5.5kw |

| DIM & WT | 950*1470*1750mm; 300kg | 1153*1654*1750mm; 400kg | 1415*1686*2130mm; 500kg |

| Vertical Form Fill Seal Machine Parameter | |||

| Model | LD-420 | LD-520 | LD-720 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm |

| Pakaging Rate | 5-60 bags/min | 5-60 bags/min | 5-55 bags/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml |

1. Automated Multifunctionality: This machine seamlessly performs tasks such as measuring, bag making, sealing, cutting, counting, and finishing product conveyors.

2. Hidden Heat and Moving Parts: The heat-generating components and moving parts are discreetly housed within a protective cover, ensuring safety and efficient operation.

3. Stainless Steel Contact Surfaces: The parts of the machine that come into contact with the product are made of stainless steel, meeting the requirements for pharmaceutical and food production.

4. Easy Mobility with Casters: The equipment is equipped with casters, making it easy to handle and move.

5. Automatic Alarm System: The machine features an automatic alarm system, enhancing safety and preventing material wastage.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail