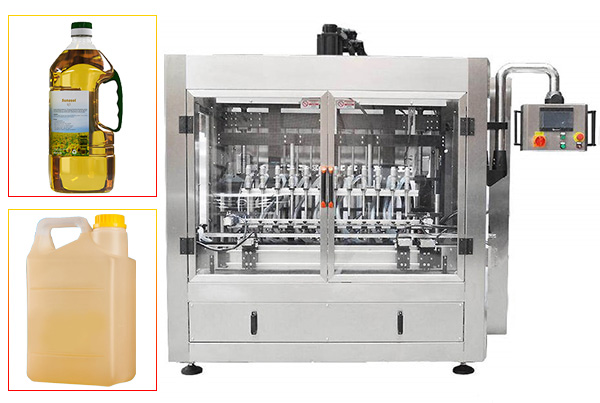

Full Automatic Olive Oil Bottle Filling Capping And Labeling lines

Model: LD-FL-10

Application:

Suitable for automatic filling, capping, and labeling of various round, flat, square, and other special-shaped bottles, cans, boxes, and cans. Applying to food, medicine, pesticide, chemical, and other industries. such as olive oil, lubricating oil, edible oil, hand sanitizer, distilled spirits, liquid detergent, shampoo, tomato sauce, etc.

Advantages:

This liquid filling line is driven by a servo motor to ensure high filling accuracy. It is controlled by PLC, a man-machine interface, and is easy to operate. The filling volume can be changed by replacing the screw gauge, and the measuring range is wide.

Application:

Suitable for automatic filling, capping, and labeling of various round, flat, square, and other special-shaped bottles, cans, boxes, and cans. Applying to food, medicine, pesticide, chemical, and other industries. such as olive oil, lubricating oil, edible oil, hand sanitizer, distilled spirits, liquid detergent, shampoo, tomato sauce, etc.

Packaging Type: Cans, Tins, Barrel, Bottles, Capsule, Cartons, Stand-up Pouch

Packaging Material: Glass, Metal, Paper, Plastic, Wood, And Others

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Parameters:

| Model | LFZ-06 | LFZ-08 | LFZ-10 | LFZ-12 |

| Filling Range | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) |

| Filling Speed | <30 bottles/min (customizable) | <40 bottles/min (customizable) | <50 bottles/min (customizable) | <60 bottles/min (customizable) |

| Measurement Accuracy | ±1% | ±1% | ±1% | ±1% |

| Power | 1KW | 1.2KW | 1.2KW | 1.5KW |

| Power Supply | 220V、50Hz | 220V、50Hz | 220V、50Hz | 220V、50Hz |

| Working Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa |

| Weight | 400kg | 450kg | 500kg | 550kg |

1. Stronger PLC software support, may realize the ideal filling operation.

2. The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple, and maintenance convenient.

3. This China's most popular product simplex filler machine jar filling machines automatic liquid filling machine uses vacuum sucking technology to ensure no leakage of the filling head during the filling production process.

4. Each filling head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correctly aiming at.

5. This machine suits for the filling of different sizes of vessels, and may change the filling sizes within a few minutes.

6. Pivotal electrical part use world-famous brands such as Mitsubishi, OMRON, and SIEMENS.

7. Optional servo filling system.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail