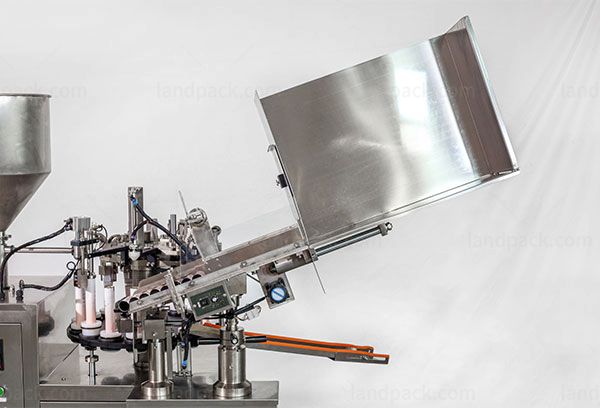

Automatic Paint Aluminium Soft Tube Filling Machine

Application:

It's applicable to paint, ointment, adhesive, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste and other liquid or paste materials. The extensional organization of the machine is made of aluminum alloy and stainless steel.

Product Description:

The product is suitable for automatic color code aligning, filling, sealing, date printing and end cutting of various plastic tubes and aluminum composite tubes. It is widely applied in daily chemical industry, medicine, food, etc.

Application:

It's applicable to paint, ointment, adhesive, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, and other liquid or paste materials. The extensional organization of the machine is made of aluminum alloy and stainless steel.

Optional Supporting Devices: three-dimensional packaging machine, cartooning machine, sealing and cutting machine, heat shrinking machine, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

Model | LFF-ZW-08 | |||

| Tube material | Aluminum / Metal tube | |||

| Tube diameter | φ15—φ70 | |||

| Tube length | 60—280(customizable) | |||

Filling volume | 10—480ml/pcs(adjustable) | |||

| Filling accuracy | ≤±1% | |||

Product capacity | 1800—4000 pcs/h(adjustable) | |||

Working pressure | 0.55—0.65Mpa | |||

Motor power | 2KW (380V/220V 50Hz/60Hz, three-phase) | |||

| Working Position | 10Automatic Aluminum Tube Filling And Sealing Machine with Cover Pcs | |||

1. High-tech product which was successfully developed and designed by adopting advanced technology from abroad and strictly meets GMP requirements. PLC controller and color touch screen are applied and made it possible for programmable control of the machine.

2. The surface panel is made of Stainless steel panel, with a beautiful appearance and durable lifetime.

3. The surface panel is made of Stainless steel panel, with a beautiful appearance and durable lifetime.

4. 16 stations using the mechanical transmission to achieve automatic indexing, and automatic tube feeding.

5. Automatic light positioning device is optional to customers' needs. Photoelectric detection to check whether the tube is available, automatical measurement, automatic filling when the tube is available, then two-way and four-fold sealing, and finally the finished product exit.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail