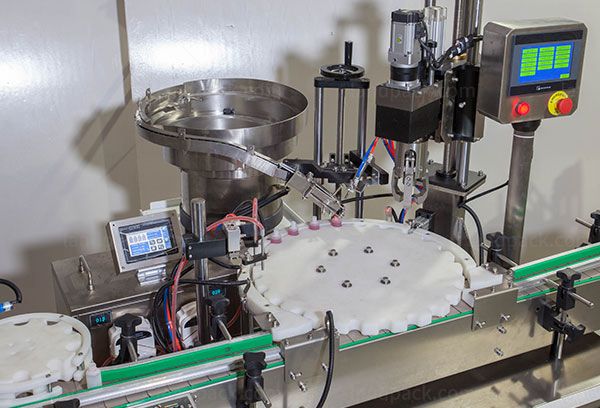

High Accuracy Liquid Ink Paint Bottle Filling And Capping Machine Line

Model: LD-AFC7C

Application:

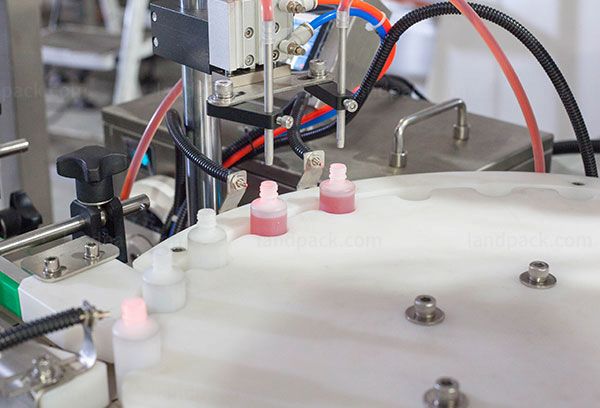

It is widely used in the filling of various semi-fluids, pastes, dense bodies, and sauce materials, such as ink, paint, cosmetics, beverages, shampoo, laundry detergent, hand washing, honey, jams, ketchup, chili sauce, bean paste, and salad dressing.

Application:

It is widely used in the filling of various semi-fluids, pastes, dense bodies, and sauce materials, such as ink, paint, cosmetics, beverages, shampoo, laundry detergent, hand washing, honey, jams, ketchup, chili sauce, bean paste, and salad dressing.

Packaging Material:

Cans, Bucket, Glass, Metal, Plastic, And Others.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| Automatic Peristaltic Pump Liquid Filling Capping Machine | |

| Model | LD-AFC7C |

| Voltage | 220V/110V, 50-60Hz |

| Power | 500W |

| Filling Pump | Peristaltic Pump |

| Working Speed | 30 bottles/min(depending on bottle size and filling material) |

| Filling Range | 1-10ML(Customizable) |

| Max Flow Rate | 1.5L/min (based on water) |

| Suitable Bottle Size | Can be customized |

| Bottle Cover Size | Can be customized |

| Packaging Size | About 1090*750*960mm(Machine); About 1080*730*580mm(Vibratory Bowls) |

| Packaging Weight | About 157kg(Machine); About 136kg(Vibratory Bowls) |

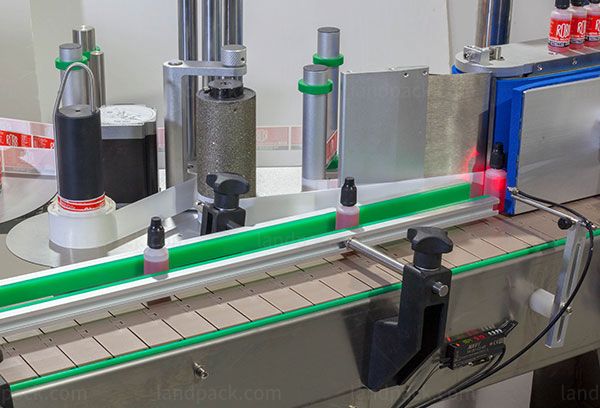

| Automatic Round Bottle Labeling Machine | |

| Name | Technical parameters |

| Model | LD-TB130 |

| Labeling range | L<300mm, H<120mm |

| Labeling speed | 60 bottles/min |

| Labeling accuracy | ±1.5mm |

| Size of the main frame | L1900*W800*H1450(mm) |

| Working voltage | 220V |

| Electricity power | 420W |

| Weight | 250W |

| Packing Dimension | 2100(L)*1150(W)*1450(H)mm |

1. Flexible Machine Design: Adapts to different bottle sizes, providing versatility in production.

2. Automatic Bottle Filling and Capping: Simplifies the process with automated filling and screw capping, ensuring easy operation.

3. Automatic Cap Feeding: Equipped with a vibration plate for precise and fast cap feeding, improving efficiency.

4. Stable High-Speed Operation: Ensures smooth running at high speeds for optimal productivity.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail