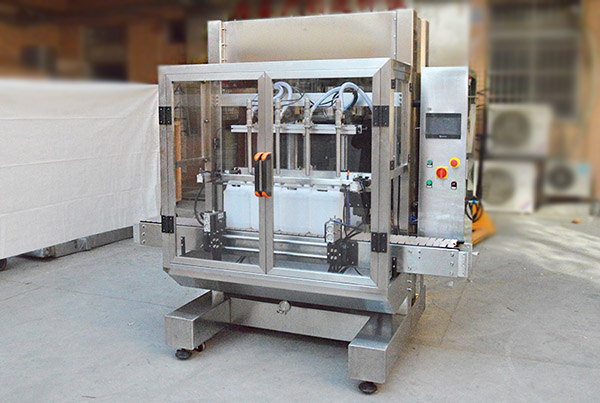

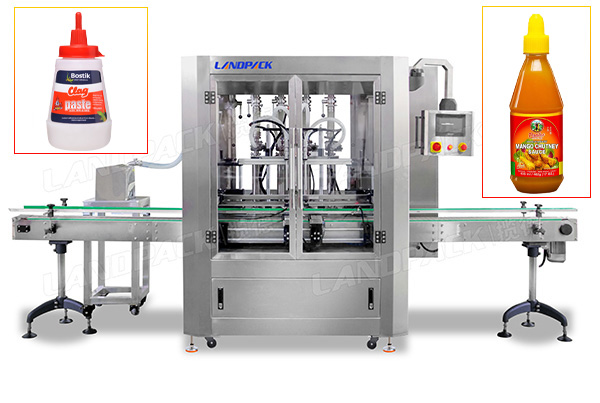

Automatic Liquid And Paste Filling Machine

Model: LF-LH-04

Application:

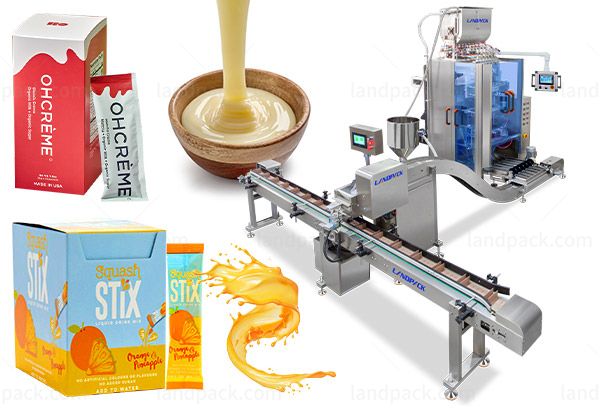

Suitable for the filling of some large particle sauce products, such as: chili sauce, mushroom sauce, spicy sauce, seafood sauce, beef sauce, bean paste, tomato paste, bbq sauce, ginger garlic paste, chutney, mayonnaise, tempeh sauce and other sauce products.

Advantages:

This machine is a kind of high and new technology filling equipment controlled by microcomputer programmable(PLC system), photoelectric sensor and pneumatic equipment.

Application:

Suitable for the filling of some large particle sauce products, such as: chili sauce, mushroom sauce, spicy sauce, seafood sauce, beef sauce, bean paste, tomato paste, bbq sauce, ginger garlic paste, chutney, mayonnaise, tempeh sauce and other sauce products.

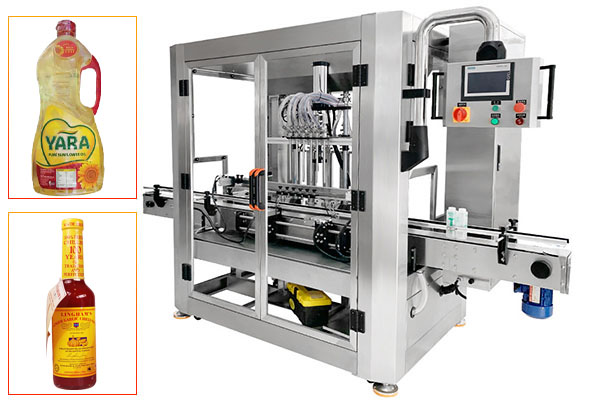

Packaging Type: Suitable for various bottle types of 500-5000ml, Suitable for filling of bottles with various shapes, such as square, round, elliptical, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Product Description:

The automatic liquid filling machine adopts the quantitative filling principle of plunger. The bottle feeding, positioning, filling and bottle output are controlled automatically by PLC, conform to the GMP standard. It is suitable for liquid filling of medicine, food, daily chemical, pesticide and fine chemical industry.

Technical parameter:

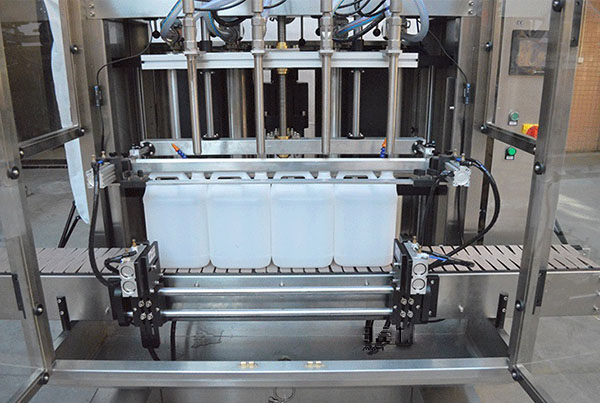

Filling heads | 4 (filling heads number is based on production speed) |

Filling range | 500-5000ml(can be customized according to customers requirements) |

Filling speed | 2000-3000 BPH |

Filling accuracy | ±1% |

Power, voltage | 50/60Hz, AC220/380V |

Air consumption | 0.4-0.8Mpa |

Dimension | 2000*1100*2100mm L*W*H |

Weight | 500KG |

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Servo motor drive piston filling machine,filling accuracy is good and stable.

4) Easy to clean, all materials contact part with quick removal structure, can also configure the customer's CIP cleaning system, cleaning time within 15 to 30 minutes.

5) Can be used for filling containers of different capacities and shapes without the need for additional replacement parts.

6) It can be used alone or connected to production lines, and can be combined with capping machine, labeling machine, inkjet printer, etc., to save labor and increase output.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail