Automatic Peanut Butter Liquid Vertical Form Fill And Seal Machine

Model: LD-320L

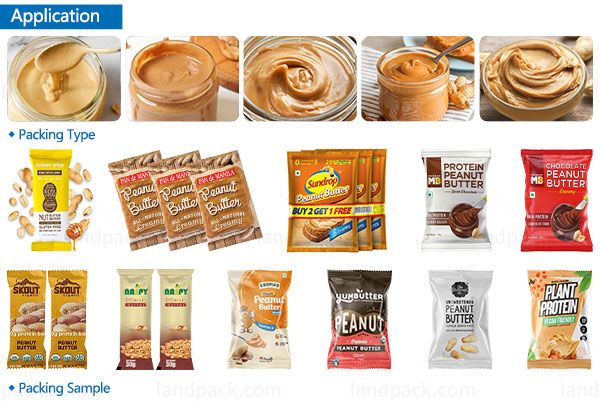

Application:

Suitable for packing various kinds of liquid objects, such as peanut butter, oli, juice, milk, honey, soysauce, ketchup, etc.

Advantage:

The whole system is linkage control, automatic feeding, stop working without materials.

Application:

Automatic Peanut Butter Liquid Vertical Form Fill And Seal Machine(LD-320L), it is suitable for filling liquids and pastes of any fluidity in various industries.

Examples:

coconut milk, soysauce, sauce, Paste, Ketchup, syrup, peanut butter, juice, honey, jam, oil, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| Model | LD-320L | LD-420L |

| Film Width | Max.320mm | Max.420mm |

| Bag Length | 80-300mm | 80-350mm |

| Bag Width | 60-200mm | 100-250mm |

| Range of Measurement | 150-1500ml | 2000ml |

| Film Roll Diameter | Max.320mm | Max.320mm |

| Packaging Rate | 10-60bag/min | 10-60bag/min |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW |

| Machine Size(L*W*H) | 1217*1015*1343mm | 1488*1080*1490mm |

| Machine Quality | About 650kg | About 680kg |

| Optional device | 1.Date Printing,2.Hole Punching Device,3.Air-filling Device,4.Tear Notch Device | |

1.Using color touch-screen and digitalized management,VIP5 has automactic stop and alarm advanced function when there is shortage of material or pouches.Thus it is easy to operate and convenient to maintain.

2.Adpoting Janpanses Panasonic PLC to draw the film, pneumatics to seal pouches, insures accuarte positioning, beautiful seal, so thatit helps to improve the operation stability.

3.Double-roller to exhaust air by extrusion,which can eliminate the air completely to achieve airless package.

4.One time completion on bag-making,weighing and adjusting, bagging, sealing, cutting and packing.

5.Solid and elegant work doors are waterproof and protective.The machine will stop automatically to avoid accident during prodution when workers open the doors to touch the operation part.

6.VIP5 can be equiped with various conveyors. Moreover, VIP5 still works stably under high temperature,so that it not only improves the production efficency, but also avoids bacteria contamination.

7.The external frame and structrue are made of stainess steel,which is clean and hygienic, up to the indicator of food hygiene quality.

8.VIP5 improves production efficiency availably,reduces the cost of labour, thus reduces the production cost.

9.Compared with manual packing,automatic packing looks more elegant and firmer.

10.Accessories are produced by large-scale manufacturer with renowned brand, which has more stable performance.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail