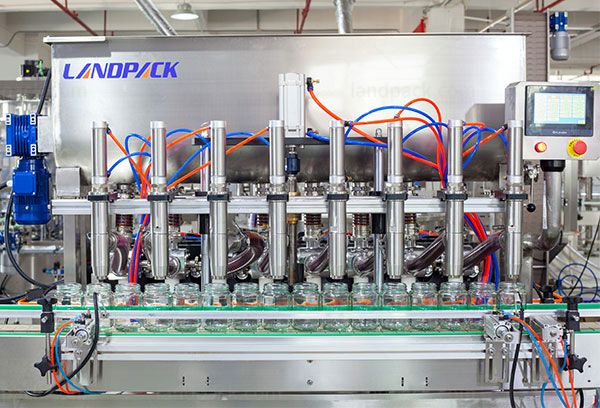

Fully Automatic Petroleum Jelly Filling Machine For Bottle/Jar

Model: LDLJ-800

Application:

It is suitable for the quantitative filling of various oils such as petroleum jelly, vaseline, face cream, ketchup, tomato sauce, mayonnaise, jam, paste, oil, yogurt, cream, hot sauce, chili sauce, honey, etc.

Advantage:

The product adopts advanced general control technology by using a PLC touch screen, and intelligent filling to make operation simpler, more convenient, and easier to study, can set the filling amount and filling speed through the touch screen

Application:

It is suitable for the quantitative filling of various oils such as petroleum jelly, vaseline, face cream, ketchup, tomato sauce, mayonnaise, jam, paste, oil, yogurt, cream, hot sauce, chili sauce, honey, etc.

Packaging Material:

Glass, Metal, Paper, Plastic, Wood, and Others.

Kindly Reminder:

| Model | LDLJ-800 |

| Filling Range | 5-100ml/10-300ml/50-500ml/100-1000ml/500-3000ml/1000-5000ml |

| Filling Speed | 25-40 bottles/min(base on oil) |

| Measurement Accuracy | ≤1% |

| Power | 110/220V 50-60HZ |

| Conveyor size | 2000*100mm(L*W) |

| Size of filling nozzle | OD15mm |

| Size of air compressor connector | Φ8mm |

1. Piston-type metering cylinder, servo-driven, suitable for filling thick sauce with large particles.

2. The special sauce anti-drip filling head and the enlarged rotary valve will not block or leak when filling large-grain sauce.

3. The horizontal mixing and horizontal pushing design improves the filling speed and solves the problem of uneven oil stratification.

4. Quality is reliable, simple operation, and durable, it is the ideal equipment for liquid filling.

5. Metal can capping machine provides customization according to the customer's product.

6. PLC control, touch bottle operation, simple and convenient operation.

7. The use of internationally famous brand electrical components, performance, and stability.

8. The machine body is made of 304 stainless steel, which is easy to clean, machine is in full compliance with GMP requirements.

9. Peristaltic pump or piston pump filling system, measuring precision, convenient manipulation.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail