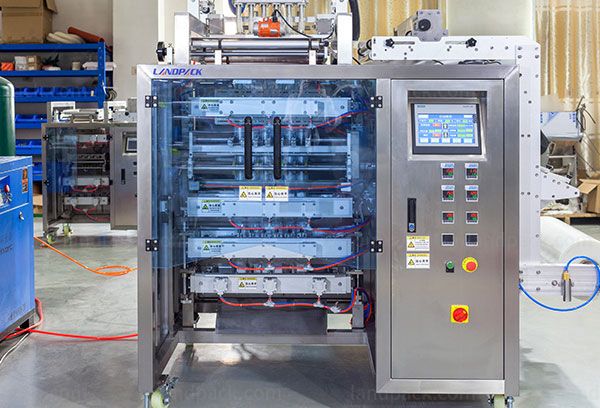

Automatic Multi Lane Sachet Pharma Medical Powder Packaging Machine

Application:

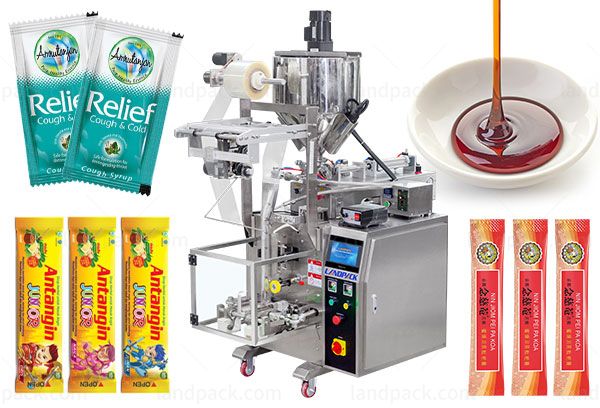

Automatic multi lane sachet powder packaging machine is suitable for many kinds of powder products, such as pharma powder, medical powder, health product powder, glucose powder, seasoning powder, insecticide powder, chemical powder, nutrition powder, etc.

Kindly Reminder:

Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Bag dimension; 2. Your product; 3. Bag shape; 4. Bag material.

Application:

Automatic multi lane sachet powder packaging machine is suitable for many kinds of powder products, such as pharma powder, medical powder, health product powder, glucose powder, seasoning powder, insecticide powder, chemical powder, nutrition powder, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

| Model | LD-480F | LD-720F | LD-960F |

| Track Number | 4-6 Track | 4-10 Track | 4-12 Track |

| Filling Method | Auger filling by servo motor | ||

| Capacity | Max. 40 cycles/min | ||

| Sachet Size | L: 45-120mm; W: 35-60mm | L: 45-120mm; W: 35-90mm | L: 45-120mm; W: 35-120mm |

| Film Width & Thickness | Max.480mm; 0.07-0.1mm | Max.720mm; 0.07-0.1mm | Max.960mm; 0.07-0.1mm |

| Sealing Type | 4 sided sealing | ||

| Air & Power | 0.8MPA, 0.8m³/min, 2.8kw | 0.8MPA, 0.8m³/min, 4.1kw | 0.8MPA, 0.8m³/min, 5.5kw |

| DIM & WT | 950*1470*1750mm, 300kg | 1153*1654*1750mm, 400kg | 1415*1686*2130mm, 500kg |

1. High production efficiency, the speed of 6 rows can reach 120-180 packages per minute, which increases production capacity and saves manpower.

2. High degree of automation: filling, loading, printing batch number, easy tearing, finished product bag output in one go, quick and easy adjustment.

3. 6 Servo motor system control, precise measurement, accurate film pulling and film feeding.

4. With dust suction device to prevent powder dust inclusion.

5. It is easy to use and is dedicated to special machines. There is no need for frequent debugging when switching between different modes. All parameters are set before leaving the factory. You only need to set simple parameters on the screen to use it.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail