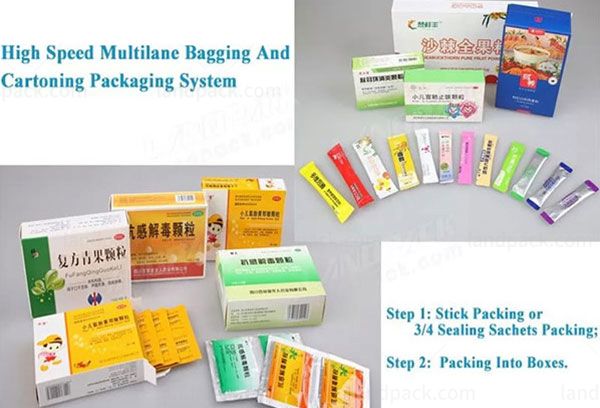

High Speed Multilane Pharma Powder Bagging And Cartoning Packaging Line System

Model: LD-480Y-2

Application:

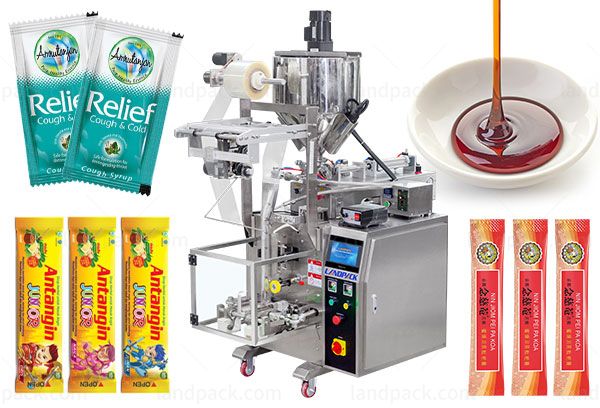

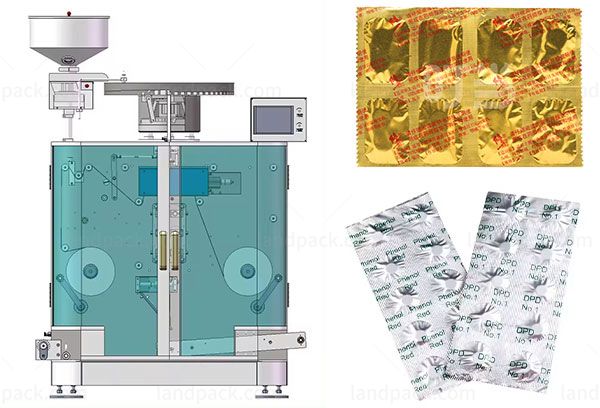

Automatic multi track powder stick sachet packing cartoning machine is suitable for many kinds of powder products, such as pharma powder, protein powder, health powder, collagen powder, medicine powder, flour, milk powder, coffee powder, glucose, medical powder, nutrition powder, etc.

Application:

Automatic multi track powder stick sachet packing cartoning machine is suitable for many kinds of powder products, such as pharma powder, protein powder, health powder, collagen powder, medicine powder, flour, milk powder, coffee powder, glucose, medical powder, nutrition powder, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examber:

| Multilane Packing Machine | |

| Model | LD-480Y-2 |

| Pouch Length | 50-120 (adjustable) |

| Pouch Width | 50-105 mm |

| Packing Speed | 60 time/min(depend by pouch size & material) |

| Filling Capacity | 0.5-50ml |

| Application Film | PET/ AL /PE, PET/PE, NY/AL/PE, NY/PE |

| Max Film Width | 900mm |

| Max Film Diameter | φ300mm |

| Film Core Diameter | φ75mm |

| Electric Source | 380v, 50hz (do as customer's request) |

| Total Powder | 15kw |

| Overall Dimension | 2200*1700*2250mm(L*W*H) |

| Machine Weight | 1500 kg |

| Packaging size | 1650*1500*2200mm(L*W*H) |

| Cartoning Machine Parameters | |

| Encasing Speed | 30-100 cartons/min |

| Carton - Quality Requirement | 250-350 g/m³ (Base on sachet or pouch size) |

| Carton - Dimension Range (L*W*H) | (70-180)mm*(35*120)mm*(14-50)mm |

| Leaflet - Quality Requirement | 60-70 g/㎡ |

| Leaflet - Unfolded leaflet specification | (80-250)mm*(90-170)mm |

| Leaflet - Fold range | 1-4 fold |

| Compressed air - Working pressure | ≥0.6Mpa |

| Compressed air - Air consumption | 200-240 L/min |

| Power supply | 220V, 50Hz |

| Motor supply | 1.1 KW |

| Machine dimension (L*W*H) | 3100*1100*1550mm |

| Machine weight | about 1400kg |

1. The adoption of brand PLC control ensures stable machine operation, while automatic counting enhances efficiency and ease of maintenance.

2. The main components are made of stainless steel, making them resistant to corrosion and suitable for various workshop environments.

3. The machine’s module structure allows customization to meet specific customer needs.

4. Key parts are controlled by servo motors, ensuring accurate performance and convenient adjustments.

5. The heat-generating components and moving parts are discreetly housed within a protective cover, enhancing safety.

6. The equipment is easy to install, disassemble, and maintain, thanks to its thoughtful design.

7. By minimizing film waste, this equipment optimizes material usage during the packaging process, contributing to cost savings.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail