High Speed & High Accuracy Tablets Pills Capsule Counting Doypack Packing Machine

Model : LDGP-160C

Application :

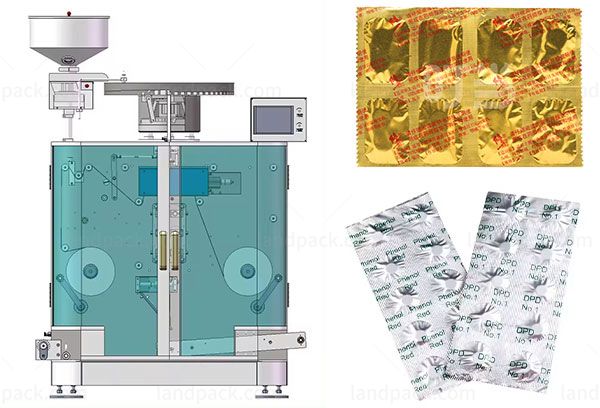

This counting packing machine is suitable for fully automatic counting nitroge gas filling sealing and packing for various granular products. Such as capsules, nutritional medicine, tablets pills, chewing gum, soft gel, vitamins, etc.

Application :

This counting packing machine is suitable for fully automatic counting nitroge gas filling sealing and packing for various granular products.

Examples :

Capsules, nutritional medicine, tablets pills, chewing gum, soft gel, vitamins, etc.

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

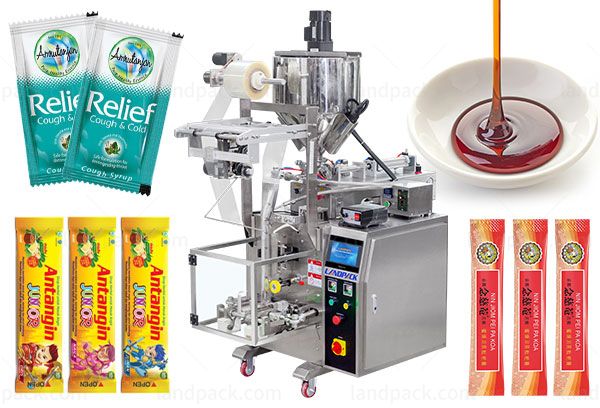

Packing Exambers :

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4-side sealing bag, stand-up bag, handbag, spout bag, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | |||

| Dimensions | 1750mm*1285mm*1360mm(L*W*H) | 2140mm*1366mm*1360mm(L*W*H) | 2140mm*1366mm*1360mm(L*W*H) | |

| Collocation | Screw metering, screw elevator | |||

1. The machine efficiently counts and packs 30-50 tablets or capsules per pouch with high precision, achieving a packaging speed of 20-25 bags per minute to significantly boost productivity and reduce labor costs.

2. User-friendly touchscreen control allows operators to easily adjust packaging parameters and settings for different product requirements.

3. Equipped with an 8-channel feeding system, it accurately counts and fills capsules (sizes 0#, 3#, 5#) and tablets into pouches with consistent reliability.

4. Compact and automated design ensures smooth operation while maintaining high-speed, high-accuracy performance for pharmaceutical and nutraceutical applications.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail