Automatic Pickles Achar Bucket Bottle Packing Machine Pickle Filling Machine Line

Model: LF-LG-006

Application:

This packaging line is highly adaptable, capable of processing both solid and liquid items, such as pickles, spicy pickles, mixed vegetables, mango, pear, garlic, ginger, pickled salads, etc.

Application :

This packaging line is highly adaptable, capable of processing both solid and liquid items, making it an ideal solution for diverse food industry needs.

1.Pickled Vegetables and Fruits:

Pickles, spicy pickles, mixed vegetables, mango, pear, garlic, ginger.

2.Sauces and Condiments:

Pickle juice, vinegar, garlic sauce, chutney, relish.

3.Fermented and Marinated Products:

Kimchi, sauerkraut, mushrooms, beans, onions.

3.Ready-to-Eat Salads:

Coleslaw, pickled salads.

4.Specialty Products:

Gourmet pickles, organic pickles, gluten-free pickles.

5.Additional Items:

Beets, carrots, herb marinades, fermented snacks.

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples :

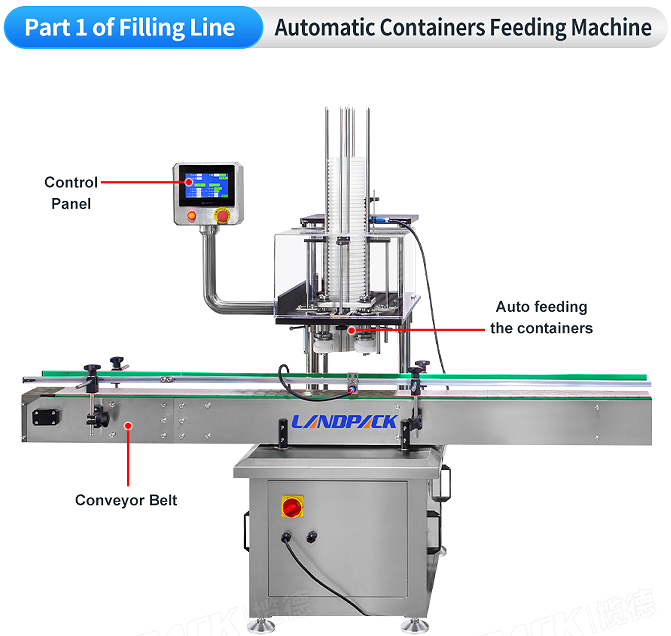

| Part 1 of Filling Line - Automatic Containers Feeding Machine | ||||||

| 1 |   | Name | Automatic screw feed bucket machine | |||

| Working pressure(MPa) | 0.6~0.8MPa | |||||

| Working power supply(V) | monophase 220V 50Hz | |||||

| Gross power(KW) | 400W | |||||

| weight(kg) | about 200KG | |||||

| Overall dimension(mm) | About 900*638*1693 | |||||

| speed(rpm) | <60rpm | |||||

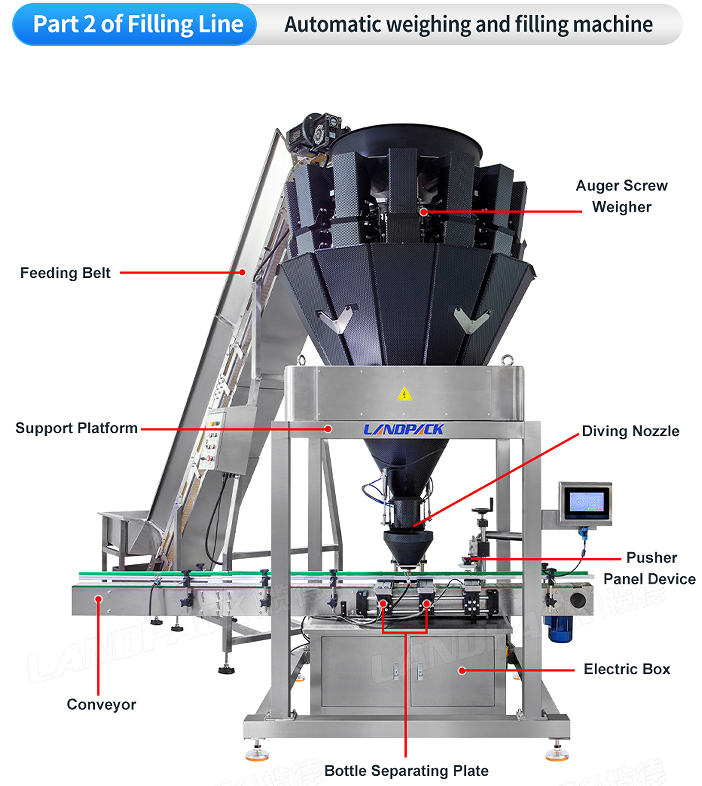

| Part 2 of Filling Line - 14 head combined screw weighing + linear filling machine | ||||||

| 2 |   | Model | LD-10 | LD-14 | ||

| Metering head | 10 | 14 | ||||

| Single weighing range | 10-1000g | 10-2000g | ||||

| Weighing accuracy | ±0.3-1.5g | ±0.3-1.5g | ||||

| Weighing speed | 70PCS/min | 120PCS/min | ||||

| Hopper capacity | 1300ml | 1300ml | ||||

| Hopper form | Double row no memory bucket | Double row no memory bucket | ||||

| Product default mode | 99 kinds | 99 kinds | ||||

| Control element | Fluorescent display tube (256*64 point 5.7 inch) | 10.4 inch LCD screen | ||||

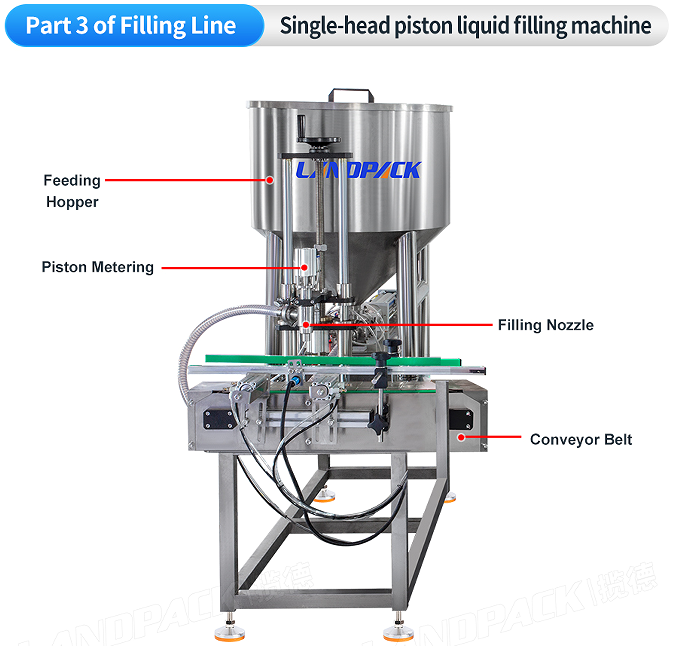

| Part 3 of Filling Line - Single-head piston metering liquid filling machine | ||||||

| 3 |   | Model | LFZ-04 | LFZ-06 | LFZ-08 | LFZ-10 |

| Filling Range | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | ||

| Production Speed | <15-25 bottles/min | <20-35 bottles/min | <30-40 bottles/min | <40-50 bottles/min | ||

| Measurement Accuracy | ±1% | ±1% | ±1% | ±1% | ||

| Power | 2KW | 2.5KW | 3.5KW | 5KW | ||

| Voltage | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz | ||

| Air consumption | 0.6-8Mpa | 0.6-8Mpa | 0.6-8Mpa | 0.6-8Mpa | ||

| Weight | 600kg | 650kg | 800kg | 800kg | ||

| Dimension | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | ||

| Part 4 of Filling Line - Double station automatic cap suction machine machine | ||||||

| Model | LD-VTYG01 | ||||

| voltage | 110V/220V | |||||

| Capacity | 15-18 bottles/min | |||||

| Applicable Container | Length:40-110mm | |||||

| Width:40-110mm | ||||||

| Height:40-110mm | ||||||

| Applicable Lid | Customizable | |||||

| Packing Size | About 2080*940*1730mm | |||||

| Gross Weight | About 261kg | |||||

| Part 5 of Filling Line - Automatic Caps Pressing Machine | ||||||

| 5 |   | Cover method | Elevator cap sorting | |||

| Capping form | Chain piece type capping | |||||

| Application bottle | According to customer's product | |||||

| Capping speed | 30-50 bottles/min | |||||

| Capping voltage | 1ph AC 220V 50/60Hz | |||||

| Air pressure | 0.6-0.8MPa | |||||

| Dimension | 1300(L)*850(W)*1660(H)mm | |||||

| Packing size | 1400(L)*950(W)*1760(H)mm | |||||

| Machine weight | About 400KG | |||||

1.Utilizes a specialized pickle auger screw weighing system with dimple-patterned, Teflon-coated plates to prevent material adhesion and ensure smooth operation.

2.Features a pickle chain plate feeding belt with a separate sauce collection pump for a secondary liquid filler, minimizing material waste and enhancing efficiency.

3.Includes a bowl feeder with a protective enclosure, ensuring both operator safety and high hygiene standards during processing.

4.Offers excellent adaptability for filling various cup sizes, with adjustable filling hopper and nozzle height for precise customization.

5.Incorporates labor-saving innovations like a bowl feeder and cap feeder, streamlining production and reducing manual effort.

6.Incorporates a smart sensor system for real-time monitoring, ensuring consistent fill levels and reducing overfill or spillage during operation.

Workflow:

1. Pickle feeding belt

2. Pickle Auger Screw Weigher

3. Bowl feeder

4. Filling hopper

5. Pusher panel device (air exhaust)

6. Sauce filling pump

7. Vacuum sucker feeding cap

8. Chain plate belt type capping machine

9. Collection table

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail