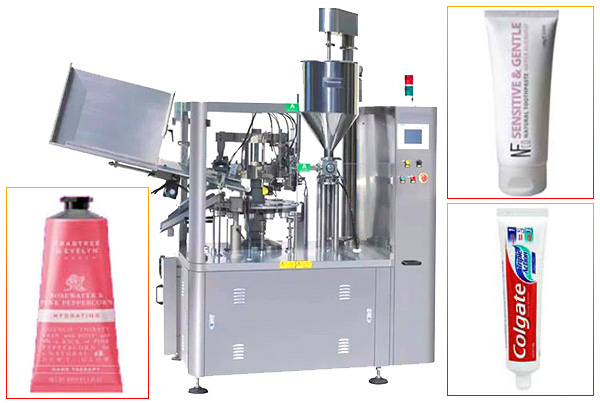

Automatic High Efficiency Tube Sealing Machine for Laminated and Aluminium Tubes

Application:

Soft tube filling and sealing machine is mainly used for the packaging containers of plastic hose material quantitative filling, sealing, this machine is widely used in pharmaceutical, cosmetic, food, chemical and other industries packaging. Such as ointments, gels, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste and other liquid or paste filling and sealing materials.

Applicable industries:

● Cosmetics, light industry (household chemicals), pharmaceutical, food and other industries for enterprise product selection to the hose for the packaging container, the device suitable for ointments, creams, gels or viscosity fluid filling, and then sealing the hose tail and print code, the system produces the finished product.

● Soft tube filling and sealing machine is mainly used for the packaging containers of plastic hose material quantitative filling, sealing, this machine is widely used in pharmaceutical, cosmetic, food, chemical and other industries packaging. Such as ointments, gels, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste and other liquid or paste filling and sealing materials.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

| Item | Heat sealing |

| Voltage | 220V/380v/50Hz/60Hz |

| Productivity | 80-100pcs/min |

| Filling volume | 3-250 ml(customized) |

| Tube diameter | 11-38mm(customized) |

| Tube length | 50-200mm(customized) |

| Max power | 7.5KW |

| Water consumption | 3-6L/min |

| Machine weight | About 1300kg |

| Dimension(L*W*H) | 2150×850×2100mm |

● Use rotary piston way, filling precision, using light point control, heated sealing all work with high precision cylinder full stroke control, easy to adjust filling volume, the filling speed can be adjusted.

● It applies to all kindsof composite tubes, plastic pipe and metal pipe filling and sealing, date printing, cut the tail.

● Sealing neat appearance, sealing strong, high accuracy, good stability.

● According to the different material properties, Optional ingredients bucket heating system, anti-leak filling head, Machine adopts imported PLC control, import the original frequency control, pneumatic, components using (AIRTAC), import original (SICK) photoelectric sensors,high stability, imported hot air flow meter and the formation of hot air heating system.

● Double Nozzle lip butter Tube Filling And Sealing Machine

● Packaging materials and filling materials Scope:

1) soft tube, plastic pipe, composite pipe.

2) ointment, cream, gel viscosity fluids agents.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail