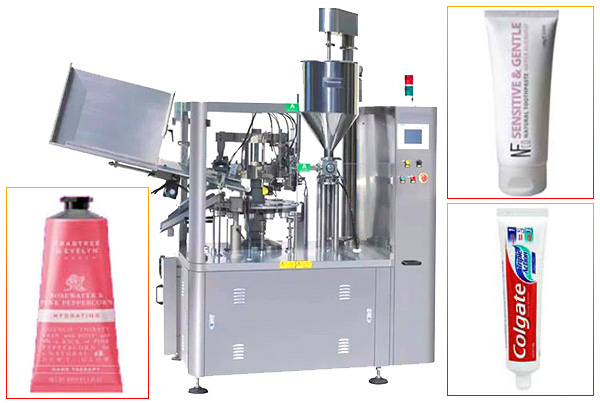

High Speed Automatic Double Working Station Plastic Tube Filling Sealing Machine

Model: LFF-GFW-10

Application:

Widely used in filling sealing medicine, daily chemical, food, chemical, cosmetics, and other industries, such as ointment, adhesive, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, etc.

Application:

Widely used in filling sealing medicine, daily chemical, food, chemical, cosmetics, and other industries, such as ointment, adhesive, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Model | LD-CFW-00 |

Sealing speed | 30-60 pcs/min |

Sealing range | 5-300 ml |

Tube height | 50-150 mm |

Tube diameter | 10-45 mm |

Size | 1100*850*1600 mm |

Power | 2.5 KW |

Weight | 550 KG |

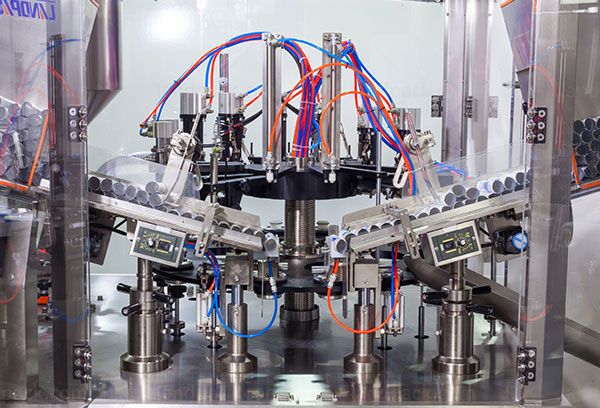

1. This feature saves labor by allowing simultaneous feeding of two tubes.

2. Having two working stations increases production speed significantly.

Workflow:

1. Double tubes feeding

2. Double mark checking

3. Double heads filling

4. Double heads tube heating sealing the first time

5. Double heads tube heating sealing the second time

6. Double date printing head

7. Double tube tail cutting

8. Output

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail