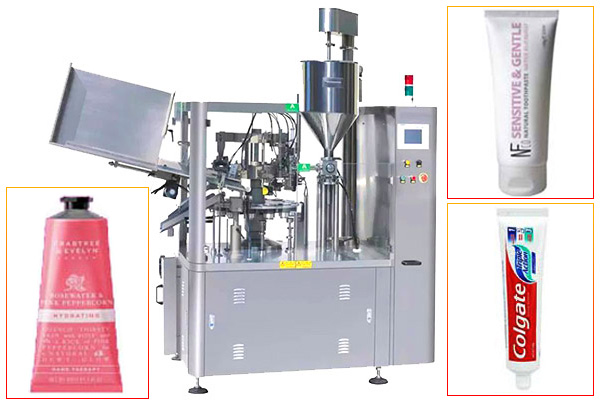

High Speed Automatic Soft Tube Filling And Sealing Machine

Model: LFF-FW-T10

Application:

High speed automatic soft tube filling and sealing machine is an ideal machine for use in the pharmaceutical, chemical, cosmetic, foodstuff and other light industries. This tube filler can be used to fill all kinds of semi-viscous and viscous products into soft plastic or flexible compound tubes.

Application:

High speed automatic soft tube filling and sealing machine is an ideal machine for use in the pharmaceutical, chemical, cosmetic, foodstuff and other light industries. This tube filler can be used to fill all kinds of semi-viscous and viscous products into soft plastic or flexible compound tubes.

Filling container: Metal Tube.

Optional Supporting Devices: three-dimensional packaging machine, cartoning machine, sealing and cutting machine, heat shrinking machine, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

| Model | LFF-FW-T10 High Speed Automatic Soft Tube Filling And Sealing Machine |

| Tube Material | Plastic tube, laminated tube,Aluminum Tube |

| Tube Diameter | Φ5mm-Φ50mm |

| Tube Length | 50-240mm (customizable) |

| Filling Volume | 5-250ml/piece (Adjustable) |

| Filling Accuracy | ≤±1% |

| Product Capacity (Pcs/min) | 60pcs/min |

| Air Supply | 0.55-0.65Mpa |

| Motor Power | 4kw (380V/220V 50Hz) |

| Heat Sealing Power | 5kw |

| Overall Dimension(mm) | 2807*1240*1900mm (L*W*H) |

| Machine Weight (kg) | 1100kg |

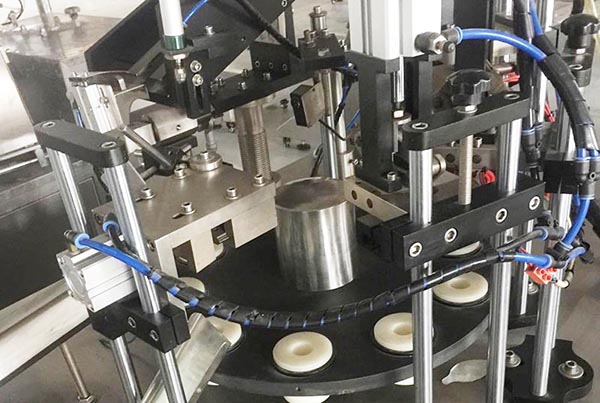

1. The Product has 12 locations and matching with manipulator, the machine is able to meet different type of tail folding, sealing requirements of plumbum tube, ALU tube, plastic tube and laminated tubes. It is a multi-purpose machine

2. Tube feeding, eye marking, tube interior cleaning (optional), material filling, sealing (tail folding), batch number printing, finished products discharging can be performed automatically (the whole procedure).

3. With external reversal feeding system, makes tube charging more convenient and tidy.

4. The mechanical linkage photo sensor precision tolerance is less than 0.2mm. The chromatic aberration scope between tube and eye mark is reduced.

5. Photo-electronic, electric, pneumatic integrative control is applied with the machine. No tube, no filling. It gives an alarm when low pressure occurs. The machine stops automatically if tube error or open the safety door.

6. Three-layer jacket instant heater with inside air heating, it won’t damage the pattern outer wall of tube and achieves firm and beautiful sealing effect.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail