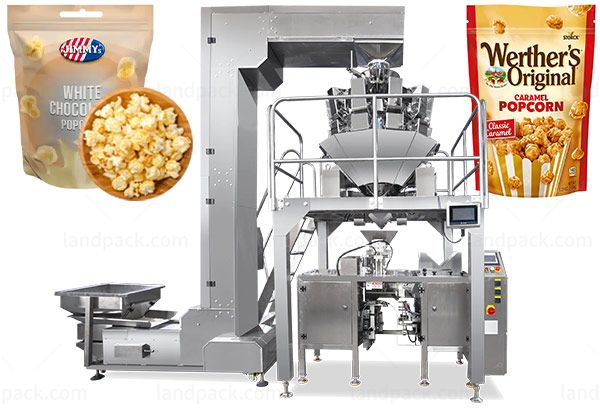

Automatic Popcorn Vertical Machine With Multihead Weigher

Model: LD-420A

Application:

Suitable for packing all kinds of granule material, sheet material, strip material and abnormity material which such as popcorn, potato chips, snacks, beef jerky, pet food, candy, sunflower seeds, peanut, nuts, beans, almond, dry fruit, vegetable salad etc.

Application:

Automatic popcorn vertical machine(LD-420A) with multihead weigher, can be used for packaging of various granular items, such as food, medicine, chemical industry and other fields.

Examples:

Popcorn, potato chips, snacks, beef jerky, pet food, candy, sunflower seeds, peanut, nuts, beans, almond, dry fruit, vegetable salad etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examples:

| Model | LD-420 | LD-520 | LD-720 | LD-900 | LD-1050 | LD-1200 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 100-800mm | 100-1000mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-505mm | 290-580mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | 400mm | 400mm | 400mm |

| Pakaging Rate | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-20bag/min | 5-20bag/min | 5-20bag/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm | Max.900mm | Max.900mm | Max.1200mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml | 1-25L | 1-25L | 1.5L-45L |

1. Multi-head combined weigher, improve metering speed and accuracy.

2. 7inch touch screen, easy operation and multiple language for choice.

3. Imported PLC system, machine performance is stable and easy for parameters adjusting.

4. With a memory function for storage ten sets of parameters. Easy to change packing product.

5. Separate PID temperature controller, suitable for various packing materials.

6. Multi-union roll film pulling system make film running more smooth.

7. Adopt double servo film-dragging structure, enable stable bag forming for perfect bag shape.

8. Sophisticated sealing framework achieve the consistency of bag sealing and cutting.

9. Machine automatically finish the process of filling, metering, bag forming, date printing, sealing and packing.

10.Low loss, labor saving, easy for operation and maintenance.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail