Application:

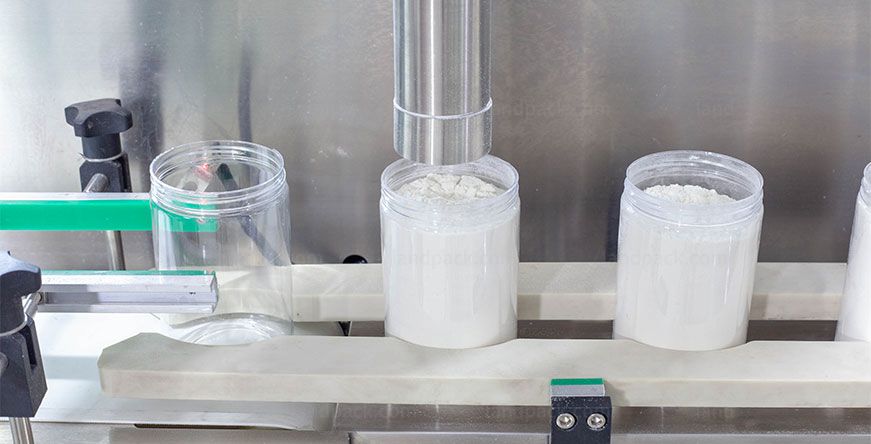

It is suitable for filling powdered materials such as milk powder, glucose, protein powder, cocoa powder, coffee powder, rice powder, solid drink and so on.

Examples: Milk powder, protein powder, coffee powder, medicine powder, chemical powder, meal replacement powder, etc.

Packaging Type: Cans, Barrel, Bottles, Capsule, Cartons, Stand-up Pouch

Advantages:

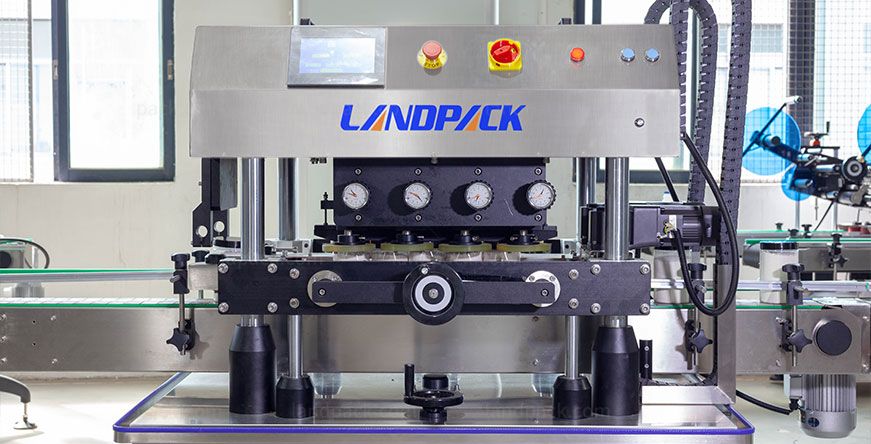

The powder-filling machine is designed in accordance with the national GMP standard. The machine can be combined with the bottling machine, the cap pressing machine, the labeling machine and other equipment to compose the pipeline.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Parameter:

| Model | LF-PJ-02 |

| Filling Weight | 10-5000g(customizable) |

| Bottle diameter | Φ30-Φ140mm(customizable) |

| Bottle height | 50mm-200mm(customizable) |

| Yield | 10-20 Bottle/min |

| Measurement accuracy | ≤500g,≤±1%;>500g,≤±0.5% (Varies due to the characteristics of the material) |

| Power | 2.5KW |

| Silo capacity | 50L |

| Power Supply | 220V/380V、50Hz/60Hz |

| Working Pressure | 0.6-0.8MPa |

| Weight | 380kg |

Features:

1. All stainless steel structures, are easy to disassemble and clean.

2. High-precision servo motor control filling, and accurate metering.

3. A variety of product adjustment parameters formulas can be stored, and ready for later use.

4. The replacement of spiral accessories can adapt to a variety of materials such as ultrafine powder to small particles.

5. Touch screen PLC control, no bottle, no filling, no cover.

6. Can be applied to food, medicine, and corrosive chemical raw materials. Centralized dust removal, no dust pollution in the workshop.

Get Price & More Detail