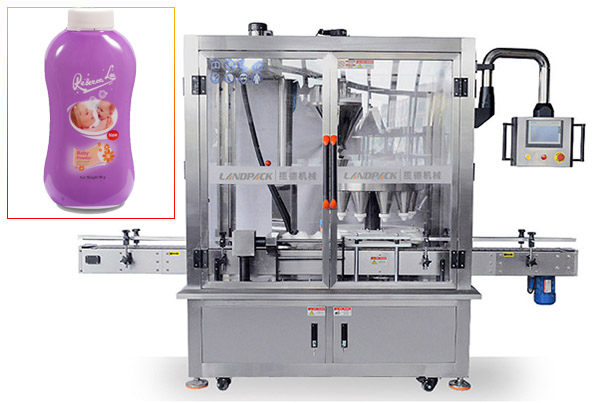

Automatic Baking Powder Seasoning Powder Small Bottle Rotary Filling Capping Labeling Machine Line

Automatic Powder Filling Capping Labeling Line

Application :

This automatic powder filling line is perfect for a diverse range of powder products, such as protein powder, milk powder, health supplements, medical powders, nutritional powders, coffee, animal feed, dextrose, monosodium glutamate, solid beverages, icing sugar, solid medicaments, and dyes. It ensures precise and efficient filling, delivering consistent, high-quality packaging for various applications across different industries.

Application :

This automatic powder filling line is perfect for a diverse range of powder products, it ensures precise and efficient filling, delivering consistent, high-quality packaging for various applications across different industries.

Examples :

protein powder, milk powder, health supplements, medical powders, nutritional powders, coffee, animal feed, dextrose, monosodium glutamate, solid beverages, icing sugar, solid medicaments, and dyes.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples :

Rotary Continuous powder filling machine | |

| Speed | 40-90 pcs/min |

| Filling weight | 10-5000g |

| Bottle diameter | Φ20mm-Φ100mm |

| Bottle height | 60mm-200mm |

| Filling accuracy | ±0.1-5g |

| Filling head | 1-4 |

| Power | 4KW |

| Voltage | 220V, 50Hz |

| Weight | 800kg |

| Round bottle labeling machine | |

| Model | LFT-YP-00 |

| Labeling Speed | 20-60 bottles/min |

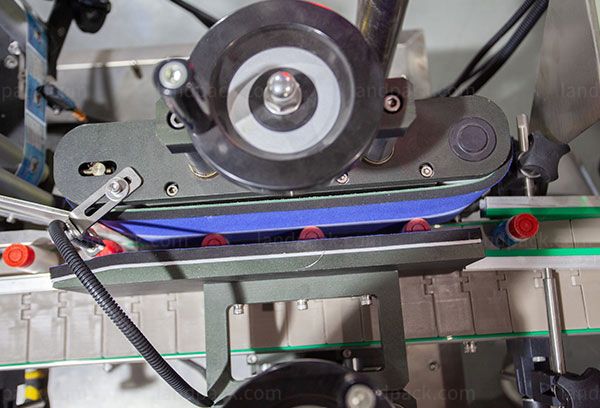

| Labeling Accuracy | ±1mm |

| Max Label Width | 100mm |

| Applicable Product Size | Φ30mm-Φ80mm |

| Applicable inner diameter of paper | Φ76mm |

| Applicable outer diameter of paper | Max.Φ330mm |

| Air Source | 4-6 KG 30L/min |

| Dimension | 2000*800*1600mm |

| Voltage | 220V 50 Hz 2000W |

| Weight | 250KG |

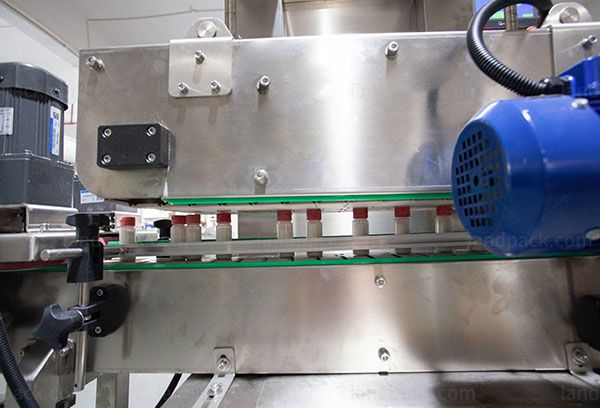

1. Automatic Bottle Feeding System: Streamlines the bottle sorting and feeding process, ensuring fast and smooth production flow.

2. Dual-Function Powder Filling Line: Capable of filling up to 90 bottles per minute, optimizing production capacity and reducing downtime.

3. Rotary Powder Filling Technology: Provides continuous, high-speed filling, perfect for operations with large volume requirements.

4. Integrated Inline System: Efficiently links powder filling with subsequent packaging processes, optimizing workflow and minimizing handling time.

5. Cap Feeder and Pressing Mechanism: Features a vibrating feeder for precise cap delivery and automatic cap pressing for secure bottle closures.

6. Round Bottle Labeling Station: Ensures precise and consistent labeling of round bottles, delivering a polished, professional look.

7. User-Friendly Touchscreen Interface: Simplifies machine operation with easy-to-navigate settings and real-time adjustments.

8. High-Precision Filling Accuracy: Maintains consistent fill volumes with minimal variance, ensuring product quality and compliance.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail