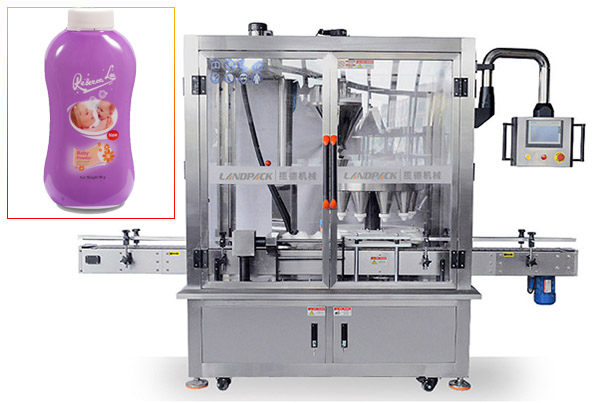

Automatic Powder Cans Tins Filling Machine With Seaming Sealing Machine

Model: LF-LX01S

Application:

It is suitable for packing Cans/ Tins of all kinds of powder product. Such as milk powder, protein powder, nutritional powder, coffee powder, chicken powder, spices powder, grains powder, etc.

The machine models of the filling line can be configured according to customer's products and requirements, such as unscrambling, sterilizing, filling, vacuum and nitrogen flushing, sealing, capping, labeling and coding.

Application:

Automatic Powder Cans Tins Filling Machine With Seaming Sealing Machine(LF-LX01S), It is suitable for packing Cans/ Tins of all kinds of powder product. Such as milk powder, protein powder, nutritional powder, coffee powder, chicken powder, spices powder, grains powder, etc.

The machine models of the filling line can be configured according to customer's products and requirements, such as unscrambling, sterilizing, filling, vacuum and nitrogen flushing, sealing, capping, labeling and coding.

Packaging Type: Cans, Tins, Bottles, Cartons, Stand-up Pouch

Packaging Material: Glass, Metal, Paper, Plastic, Wood, Other.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

| Name | Automatic powder bottle production line |

| Filling weight | According to customer requirement |

| Power supply | 3 phase 380V 50Hz |

| Compressed air consumption | 6kg/cm² |

| Air consumption | 1.45m'/min |

| Bottle material | 307#/401#/502#/300#/PET,glass bottle, tinplate |

| Filling specification | Changing the mold of no defective filling machine and nitrogen filling & filling machine can canning products of various specifications |

| Packing speed | 15-55 bags/min |

| Measurement accuracy | ≤ ± 0.5% |

1. Servo and pneumatic system control tank and horizontal moving tank, accurate positioning and fast speed, stable performance and high accuracy;

2. The filling machine adopts weighing filling measurement, and the accuracy is higher than that of screw measurement;

3. The filling machine adopts the lower weight filling metering, which is more accurate than the screw metering

4. It is equipped with 8-position can sealing machine to improve production capacity and save manpower.

5.More stable, Adopted 1.5mm thickness 304 stainess steel for the whole frame,The parts in contact with materials are made of food-grade stainless steel.

6.Equipped with a weight sensor to ensure the accuracy of filling.

7.Equipped with dust removal device and negative pressure pipe, it can effectively suck away the raising powder in the filling process and effectively protect the workshop environment.

8. Equipped with 8-station can seamer to increase production capacity and save manpower;

9. Wide applicability, Changing screw can measure different weight and precision;

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail