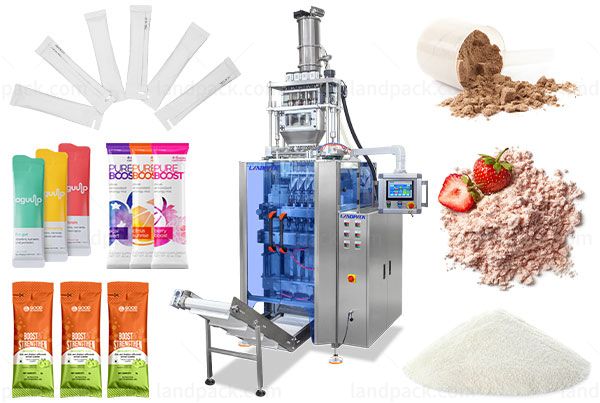

Automatic Powder Pre-made Pouch Doypack Filling Machine

Model: LD-8200D/ 8240D/ 8300D

Application:

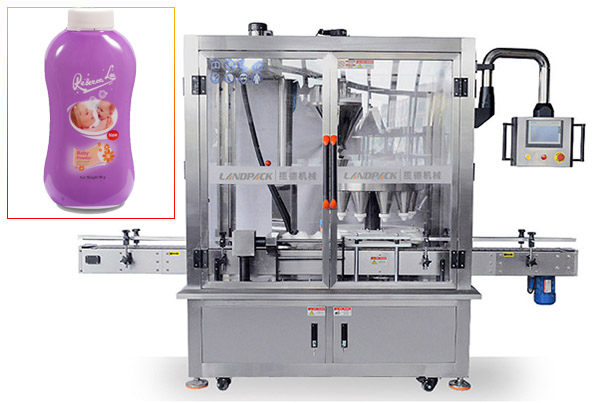

Automatic powder pre-made pouch doypack filling machine(LD-8200D/ 8240D/ 8300D), it is suitable for automatic packing for Powder: milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc.

Suitable Pouches:

All type of heat sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout ect.

Application:

Automatic powder pre-made pouch doypack filling machine(LD-8200D/ 8240D/ 8300D), it is suitable for automatic packing for Powder: milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc.

Suitable Pouches: All type of heat sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout ect.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Parameters:

Model: LD-8200D/ 8240D/ 8300D

Bag Size: W: 100-300mm L: 100-450mm

Filling Volume: 5-2500g (Depending on type of products)

Capacity: 25-60 bags/min (The speed depends on type of products and packaging material used)

Package Accuracy: Error≤±1%

Compress Air Requirement: ≥0.8m³/min supply by user

Optional configuration:

1. Material weighing & filling machines

2. Platform

3. Check weigher

4. Material elevator

5. Finished product conveyor

6. Metal detector

Work Process:

1. Bag giving

2. Date coding

3. Bag opening

4. Filling and vibrating 1

5. Filling and vibrating 2

6. Product settling after filling by vibrating

7. Heat sealing

8. Forming and product output

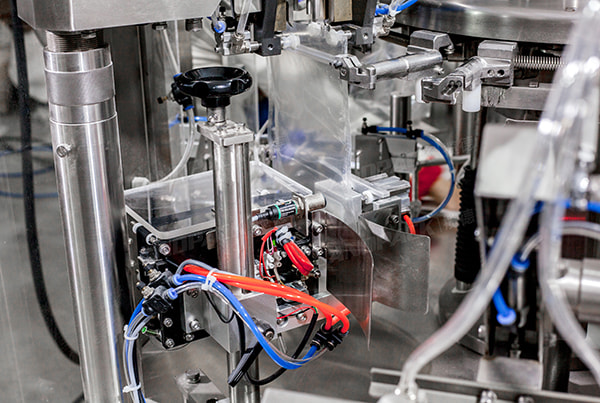

1. Full automatic intermittent rotary preformed bags dispensing, opening and closing machine combined with automatic auger powder filler, bulk screw feeder and product bulk hopper.

2. Safety guard protected for high speed and consistent production heavy duty components and parts are selected for machine durability.

3. Hygienic construction and easy cleaning operators friendly design touchscreen control system.

4. Adopt advanced PLC, mate with touch screen and electric control system, the man-machine interface is friendly.

5. Dust control and extractor system on special request.

6. Automatic checking system can check bag situation, filling and sealing situation.

The system shows:

1.no bag feeding, no filling and no sealing.

2.no bag opening/opening error, no filling and no sealing

3.no filling, no sealing.

Noted: We can customize the suitable one for you according to your requiredment.

Just Tell us: Weight or Bag Size required.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail