High-Precision Powder Stand Up Pouch Doypack Packing Machine

Model: LDSP-160D/ 210D/ 260D

Application:

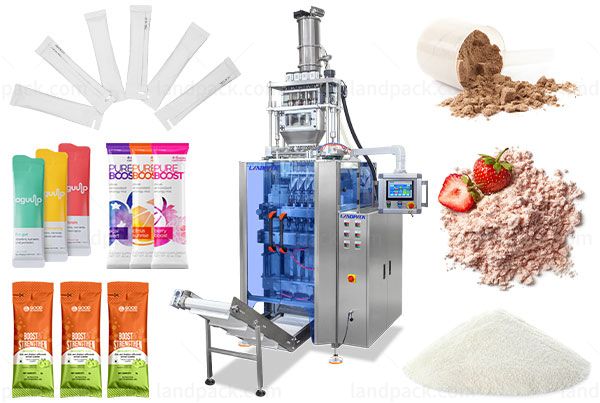

High-precision powder stand up pouch doypack packing machine(LDSP-160D/ 210D/ 260D), it is suitable for packing various of powder, such as milk powder, protein powder, collagen powder, premium whey powder, coffee powder, food additives, condiments, tapioca powder, nutrition powder, coconut powder, pesticide powder, fertilizer granules etc.

Bag type: 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc.

Application:

High-precision powder stand up pouch doypack packing machine(LDSP-160D/ 210D/ 260D), it is suitable for packing various of powder, such as milk powder, protein powder, collagen powder, premium whey powder, coffee powder, food additives, condiments, tapioca powder, nutrition powder, coconut powder, pesticide powder, fertilizer granules etc.

Bag type: 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examber:

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

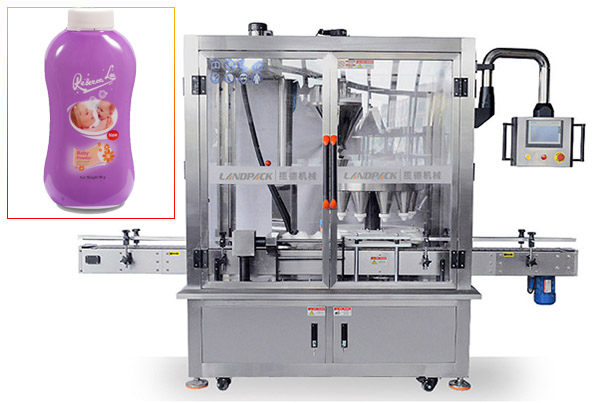

| Collocation | Screw metering,screw elevator | |||

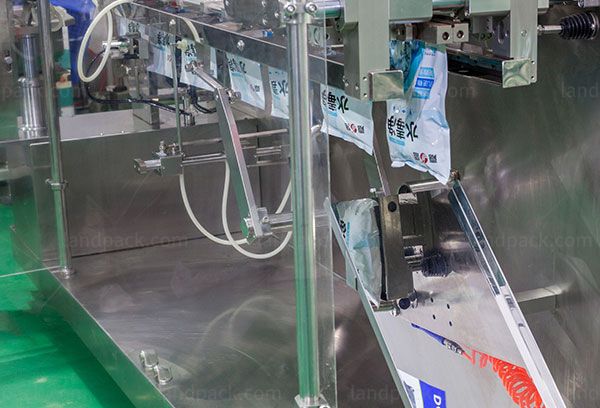

1. The bag feeder is easy to place the pouch with pressing-pouch accessory.

2. It's with imported gravity sensor to read whether there is product there. No product, not seal to save pouch.

3. With color touch screen for operation.

4. The machine adopts all stainless steel 304 appearance, and some accessories are processed with acid and salt-resistant anti-corrosion treatment layer.

5. Majority of accessories will use 304 stainless steel and aluminium oxide;

6. Optional accessories: inkjet printer, thermal printer, exhaust air, punching and etc;

7. Accurate measurement with 0.01% error;

8. high speed and high production capacity;

9. Low noise of mechanical operation;

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail