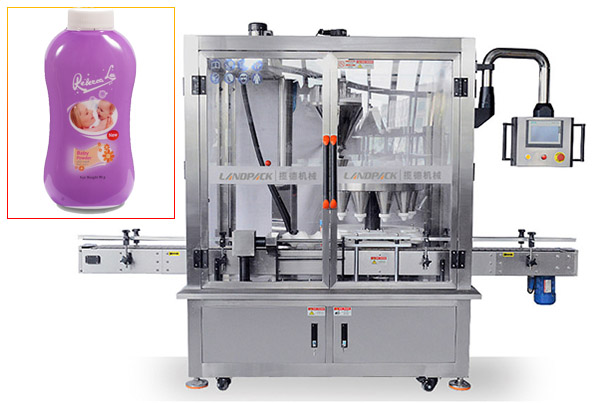

High Speed Small Dose Powder Rotary Filling Machine

Model: LF-PJ-001H

Application:

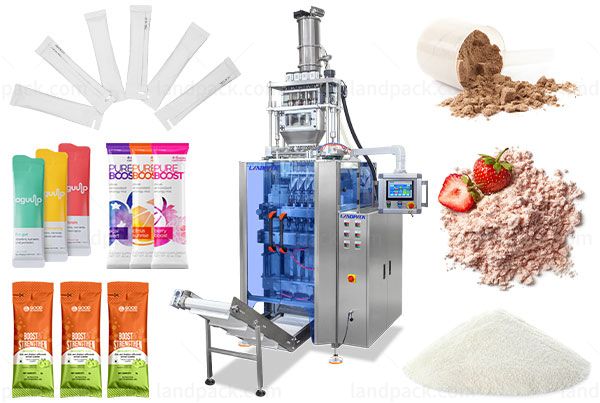

High speed small dose powder rotary filling machine(LF-PJ-001H), it is filling all kinds of small-dose powders. Such as various meal replacement powders, seasoning powders, flours, milk powders, chili powders, nutritional powders, etc.

Introduction:

It can be applied to other containers by replacing the metering screw, and it is widely used. It can automatically complete the packaging processes such as loading, quantitative filling, sealing, labeling and coding.

Application:

High speed small dose powder rotary filling machine(LF-PJ-001H), it is filling all kinds of small-dose powders. Such as various meal replacement powders, seasoning powders, flours, milk powders, chili powders, nutritional powders, etc.

Packaging Type: Cans, Tins, Barrel, Bottles, Capsule, Cartons, Stand-up Pouch

Packaging Material: Glass, Metal, Paper, Plastic, Wood, Other.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

| Model | LF-PJ-001H |

| Production Capacity | 40-80Cans/min (decided according to material and filling volume) |

| Filling Range | 10-50g Adjustable (change screw attachment) |

| Number of Filling Heads | 1 head |

| Filling Accuracy | ±0.5% |

| Power Supply | 220V、50Hz |

| Power | 3KW |

| Machine Weight | about 300kg |

| Dimensions | 2500×800×2200mm |

It conforms to the national GMP standard and can pass the national food hygiene certification.

Contact with materials is made of 304 stainless steel, which can be used for packaging of general corrosive chemical products.

PLC-touch screen control system, stable work, strong anti-interference, high weighing accuracy, convenient man-machine interface operation.

It is convenient and quick to adjust the machine to suit all kinds of filling containers. 10 sets of parameters can be stored.

The filling screw is driven by a servo motor, which has the advantages of accurate positioning, high precision, fast speed, large torque, long life, settable speed, and good stability.

The mixing adopts Taiwan-made maintenance-free geared motor: low noise, long life, and lifetime maintenance-free.

Changing materials can automatically adjust the packaging weight.

Equipped with dust filtering device, and the filling accessory is equipped with a dust removal system to protect the workshop environment.

It can meet the canning needs of a variety of materials from superfine powder to small particles.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail