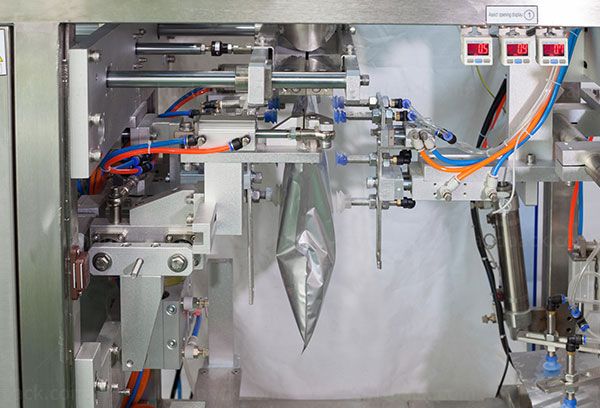

Low Price Powder Mini 3/4 Side Sealing Pouch Doypack Machine (Single station)

Model: LDSP-160D/ 210D/ 260D

Application:

It is widely applicable to the automatic packaging of various powder products, and it can be applied to the automatic packaging of various granular, block, liquid and other products by replacing the metering device.

It can auto finish material feeding, weighing, premade pouch pick-up, open, fill and seal, etc. Premade pouch can be 3/-side-seal, gussette pouch, standup pouch no-zip-lock.

Application:

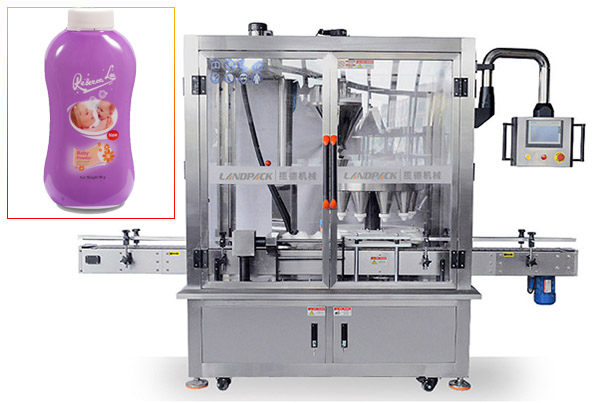

Low Price Powder Mini 3/4 Side Sealing Pouch Doypack Machine(LD-300D/LD--430D), It is suitable for packaging various powder products, such as protein seasoning powder, coffee powder, powder, milk powder, chilli powder, dandelion powder, spice powder, pesticide powder, collagen powder, veterinary drug powder, tea powder, traditional Chinese medicine powder, organic protein powder, flour, feed additives, traditional Chinese medicine powder, and other powders. and it can be applied to the automatic packaging of various granular, block, liquid and other products by replacing the metering device.

Bag type: Premade pouch can be 3-side-seal, gussette pouch, standup pouch with zipper or no-zip-lock. Ideal choice for milk powder, glucose, seasoning, washing powder, chemical materials, pesticide, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examber:

Model | LDB-300D |

Pouch Type | Four-side Sealed Bags, stand-up pouches, zipper bags, three-side sealed bags, paper bags, etc. |

Capacity | 10-20 bags/min |

Bag Size | Width:60-120mm Length:55-130mm |

Filling Volume | 15-200g |

Dimension | 1800*1200*1500mm(L*W*H) |

Weight | 1600KG |

Compress air requirement | ≥0.8m³/min |

1. Single station prefabricated bag packaging machine, small footprint

2. Easy to operate,adopt advanced PLC from Japan Mitsubishi, mate with touch screen and electric control system, the man-machine interface is friendly.

3. Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

3. Safety device: Machine stop at abnormal air pressure, heater disconnection alarm

4. The width of the bags could be adjusted by electrical motor.

5. Supporting powder vacuum cleaner for dust removal to create a clean workshop

6. It matches with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust.

7. The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

8. With different feeders changed to pack solid, liquid, thick liquid ,powder and so on

9. The packaging bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail