Automatic Powder Stick Bag Packing Machine Line With Vacuum Mixing Tank

Model : LDBS-280D

Application :

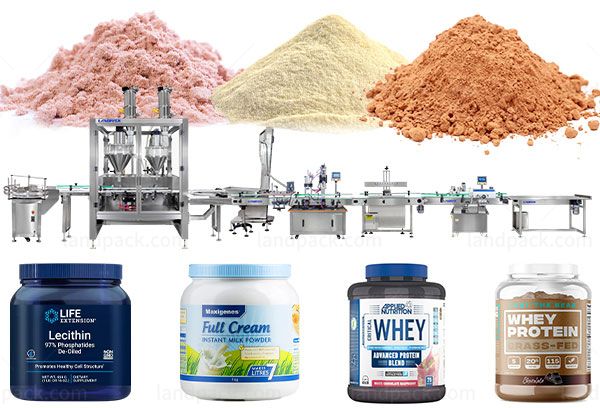

The fully automatic powder stick bag packaging line has an automatic powder mixer, vacuum feeding system, screw metering system, ribbon coding and weighing function. This production line is very suitable for packaging various powders, such as protein powder, medicinal powder, spices, tea powder, milk powder, coffee powder, flour, etc.

Application :

The fully automatic powder stick bag packaging line has an automatic powder mixer, vacuum feeding system, screw metering system, ribbon coding and weighing function. It can provide efficient and precise packaging solutions, designed for contactless powder packaging process, ensuring safety and hygiene.

Examples :

Protein powder, medicinal powder, spices, tea powder, milk powder, coffee powder, flour, etc.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packing solutions according to your product characteristics.

Packaging Examples :

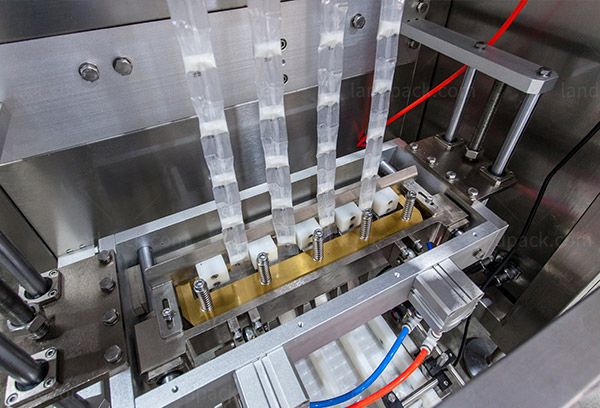

| Model | LDBS-280D | LDBS-560D |

| Lane number | 4-6 Lines | 8-12 Lines |

| Filling Method | Auger filling by servo motor | |

| Capacity | Max.35 cycles/ min | |

| Sachat Size | L: 50-180mm; W: 17-30mm | L: 50-180mm; W: 17-30mm |

| Film width & Thickness | Max.280mm, 0.07-0.10mm | Max.560mm, 0.07-0.10mm |

| Sealing type | Back sealing/Stick bag | Back sealing/Stick bag |

| Cutting type | 1. Straight cutting; 2. Zig zag cutting; 3. Round cutting; 4. Irregular | |

| Air & Powder | 0.8Mpa, 0.8m³/min; 3.5kw | 0.8Mpa, 0.8m³/min; 5.5kw |

| Dimension & weight | 1385*918*2005mm; 350kg | 1685*1300*2005mm; 550kg |

1.Combines storage, sorting, mixing, feeding, filling, packing, sealing, and output, streamlining the entire production process with automatic weight checking and rejection for efficiency.

2.Auger screws ensure precise powder filling, with consistent results and secure, high-quality sealing to maintain packaging integrity.

3.Equipped with an automatic vision system for immediate weight inspection, ensuring that each product meets quality standards during the production process.

4. Fully automated, zero-human intervention system delivers high-speed, consistent production with reliable output quality.

5.The production line adheres to rigorous safety and hygiene standards, minimizing manual intervention and maintaining a clean environment throughout the process.

6.The system's advanced technology guarantees accurate powder dosing, filling, and sealing, ensuring uniform product quality and packaging performance.

7.The automated system ensures continuous and consistent production, reducing human error and optimizing operational efficiency for high-volume output.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail