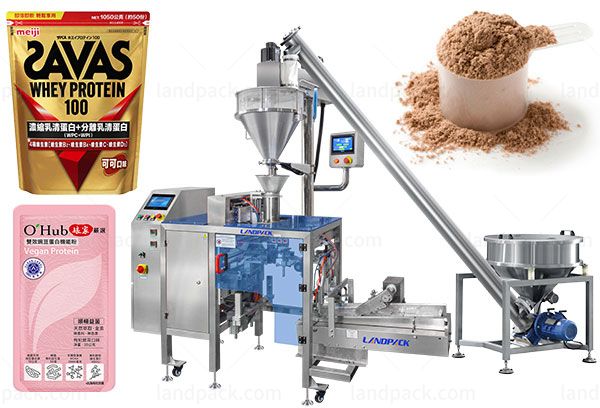

Automatic Protein Powder Premade Pouch Doypack Packing Machine

Model:LD-8200D/ 8240D/ 8300D

Application:

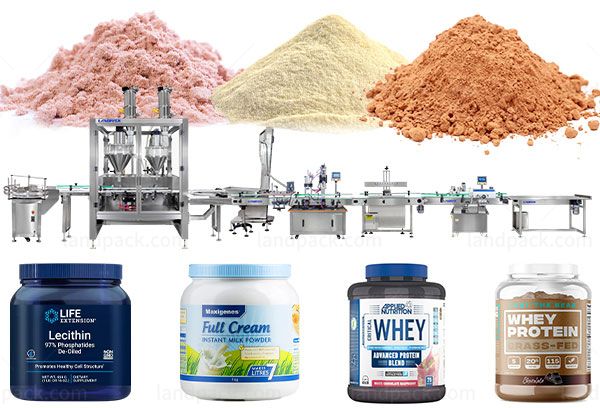

Suitable for packing those powder and fine granules that are easy to flow or have poor flowability, such as protein powder, milk powder, nutrition powder, coffee powder, yeast, health powder, medicine powder, glucose, medical powder, flour, etc.

Suitable Pouch: 3 /4 side edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc

Application:

Suitable for packing those powder and fine granules that are easy to flow or have poor flowability, such as protein powder, milk powder, nutrition powder, coffee powder, yeast, health powder, medicine powder, glucose, medical powder, flour, etc.

Suitable Pouch: 3 /4 side edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc

Kindly Reminder:

We have experienced team of R & D engineers who can customize packing solutions according to your product characteristics.

Packaging Examber:

| Model | LD-8200D/ 8240D/ 8300D |

| Packing material | 3 /4 side edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

| size | W: 100-300mm L: 100-450mm |

| Filling range | 5-2500g (Depending on type of products) |

| Packing speed | 25-60 bags/min (The speed depends on type of products and packaging material used) |

| Average precision | ≤ ±1% |

| Total power | 2.5KW |

| Dimensions | 1900mm X 1570mm X 1700mm(L*W*H) |

| Work flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

1. Automatic spoon feeding, accurate and stable.

2. The vacuum cleaner prevents the powder from sticking to the bag mouth and keeps the machine station clean and tidy

3. Screw feeding visual window, removable elevator, easy to clean and maintain

4. Accurate measurement, suitable for various premade pouch and doypack, beautiful packaging.

6. Full automatic intermittent rotary preformed bags dispensing, opening and closing machine combined with automatic auger powder filler, bulk screw feeder and product bulk hopper.

7. Safety guard protected for high speed and consistent production heavy duty components and parts are selected for machine durability.

8. Hygienic construction and easy cleaning operators friendly design touchscreen control system.

9. Adopt advanced PLC, mate with touch screen and electric control system, the man-machine interface is friendly.

10. Dust control and extractor system on special request.

11. Automatic checking system can check pouch situation, filling and sealing situation.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail