Multifunction Semi Automatic Powder Mixing and Filling Machine Line

Model : LD-2500L

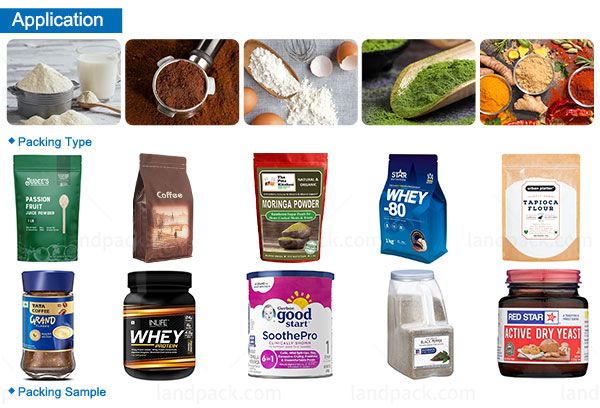

Application :

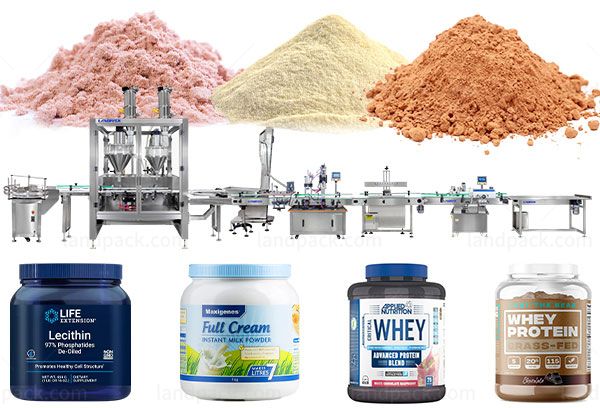

This automated filling system is designed for precision packaging of diverse powdered products, including protein powders, nutritional supplements, chemical powders, pharmaceutical compounds, spice powder, corn starch, flour, coffee powders, dairy powders, and meal replacement formulations.

Application :

This automated filling system is designed for precision packaging of diverse powdered products, including protein powders, nutritional supplements, chemical powders, pharmaceutical compounds, spice powder, corn starch, flour, coffee powders, dairy powders, and meal replacement formulations.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers :

| Name | Auger Filler powder machine |

| Max Weight | 10-1000g/time |

| Container size | Φ 80-210mm H100-330mm(customized) |

| Filling weight | 900g-2500g(customized) |

| Filling accuracy | 500g, ≤±1% |

| Filling speed | 10-30bottles/min(depend on the material and weight) |

| Auger Filler hopper | 2500L |

| Power supply | Three phase 380V or single phase |

| Total power | 3.5 KW |

| Total weight | 420kg |

| Dimension | 2000*900*1850mm |

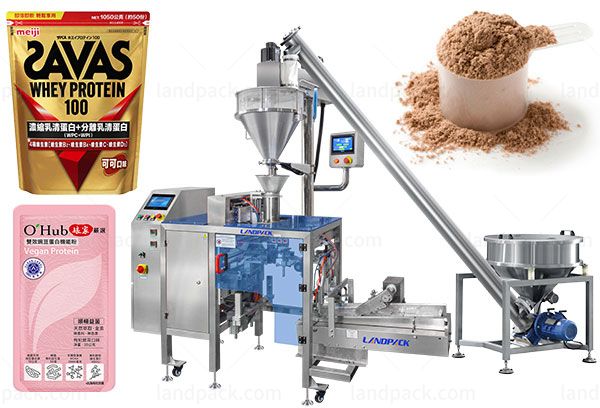

1.High-Capacity Mixing – A 2000L powder mixer ensures uniform blending for diverse powders, supporting high-volume production.

2.Accurate Semi-Automatic Filling – Precisely dispenses 200g–1kg of mixed powder into bags, bottles, or cans with consistent results.

3.User-Friendly Control – Intuitive PLC and touchscreen interface for effortless operation and adjustments.

4.Automated Material Handling – Integrated sensors detect low hopper levels and trigger conveyor refilling, minimizing downtime.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail