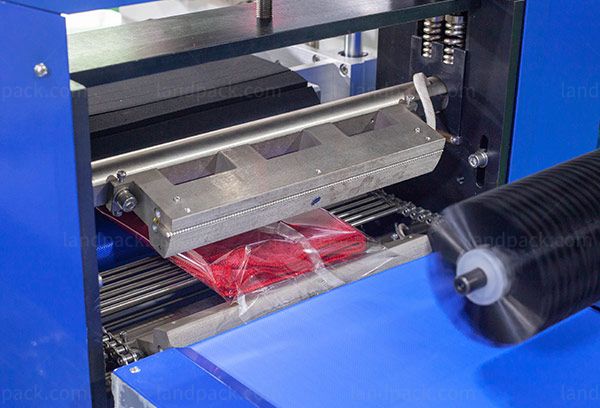

Automatic Sanitary Napkin Flow Packing Packaging Machine

Model: LP-700X

Applicaiton:

Suitable for packaging various kinds of regular objects like sanitary napkins, biscuits, pies, chocolates, bread, instant, noodles, mooncakes, drugs, daily applications, industrial parts, paper boxes, and trays. etc.

Application:

This machine can be applied to sheet products that require sealing on the sides, such as the following products;

Examples:

Sanitary napkins, biscuits, pies, chocolates, bread, instant, noodles, mooncakes, drugs, daily applications, industrial parts, paper boxes, and trays. etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

| Type | LP-450X | LP-600X | LP-700X |

| Film width | Max.450mm | Max.600mm | Max.700mm |

| Bag length | 150-450mm | 160-500mm | 180-600mm |

| Bag width | 50-180mm | 100-280mm | 100-330mm |

| Product height | Max.80mm | Max.110mm | Max.110mm |

| Film roll diameter | Max.320mm | ||

| Packaging rate | 40-150 bags/min | 20-150 bags/min | 20-130 bags/min |

| Power | 220V, 50/60Hz, 2.8kw | 220V, 50/60Hz, 2.8kw | 220V, 50/60Hz, 2.8kw |

| Machine size | (L)4150*(W)820*(H)1450mm | (L)4300*(W)920*(H)1460mm | (L)4380*(W)980*(H)1480mm |

| Machine quality | About 650kg | About 680kg | About 720kg |

| Remarks | optional air-filling device / optional angle folding | ||

| Film material | OPP/ PE/ PVC/ OPP/ CPP/ PT/ PE/ KOP/ CPP/ Aluminum Coating Film/ Aluminum Film | ||

1. Three Servo Motor Control: Allows for setting and cutting bag length in one step, saving time and film.

2. User-Friendly Interface: Features easy and quick setting and operation.

3. Self-Failure Diagnosis: Provides a clear display of any faults.

4. High Sensitivity Photoelectric Eye Color Tracing: Ensures precise cutting and sealing position with numerical input for accuracy.

5. Temperature Independent PID Control: Adapts to different materials for optimal packaging.

6. Positioned Stop Function: Prevents knife sticking and film waste.

7. Simple Driving System: Offers reliable performance and easy maintenance.

8. Software-Based Control: Facilitates function adjustments and technical upgrades.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail