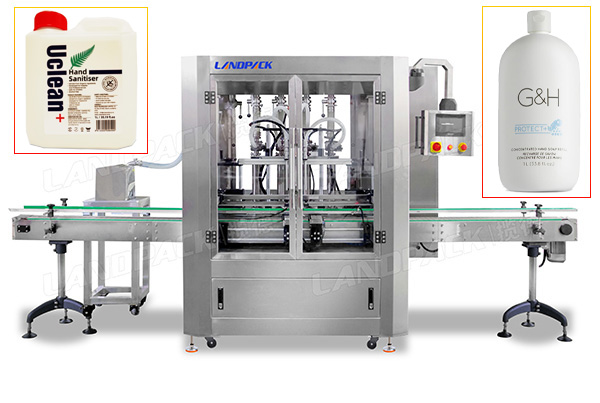

Automatic Hand Sanitizer Alcohol Liquid Bottle Filling Machine

Model: LF-LH-10

Application:

Automatic liquid bottle filling machine(LF-LH-04), it is suitable for the filling of various liquids, pastes and sauces, such as alcohol, disinfectant, disposable hand sanitizer, honey, chili sauce, tomato sauce, pearl milk tea, orange juice, etc., with strong versatility.

Main Process Description:

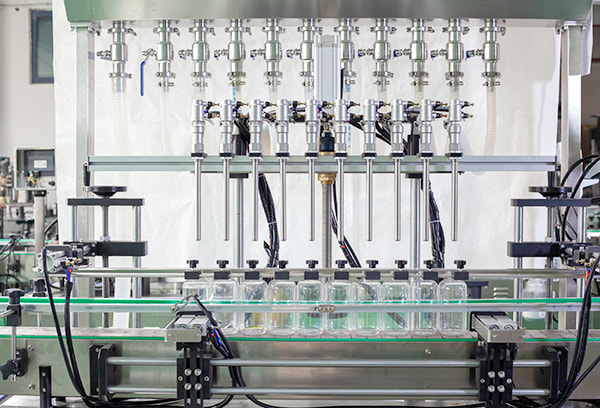

Automatic bottle feeding → positioning bottle mouth → filling valve decline → filling → filling valve rise → positioning release → automatic bottle out

Application:

Automatic liquid bottle filling machine(LF-LH-04), it is suitable for the filling of various liquids, pastes and sauces, such as alcohol, disinfectant, disposable hand sanitizer, honey, chili sauce, tomato sauce, pearl milk tea, orange juice, etc., with strong versatility.

Packaging Type: PET plastic bottles, glass bottles, glass jars, tinplate cans, bottles, cans, tins, barrel, capsule, cartons, stand-up pouch

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Brief Introduction:

This machine is a high-tech filling equipment that is programmable by PLC, photoelectric sensor, and pneumatic execution. The filling machine is suitable for liquids with good fluidity, with a viscosity range of 1-100cp, such as hand sanitizer, disinfectant, mineral water, juice, milk, oral liquid, pesticide and chemical liquids and so on. The machine has the characteristics of wide application, high degree of automation, high filling precision, high production efficiency, simple operation and long service life.

Parameters:

| Model | LFZ-10 |

| Filling Range | 50-1000ml(customizable) |

| Production Speed | <50Bottle/min (the range of 100-500ml) |

| Measurement Accuracy | ±1% |

| Bottle Diameter | Φ30mm-Φ120mm(customizable) |

| Sealing Height | 30mm-240mm(customizable) |

| Control system | PLC |

| Power | 1.2KW |

| Power supply | 220V、50Hz |

| Airconsumption | 0.6-1m³/min |

| Equipment Material | 304 |

1. It is suitable for the filling of containers of different specifications, and the filling bottle specifications can be switched within a few minutes;

2. Users can choose the number of filling according to their own production capacity to determine the number of filling heads;

3. Each filling head is equipped with an alignment device to ensure accurate filling positioning;

4. Use advanced pneumatic filling valve to ensure that there is no dripping or drooling during the filling process;

5. The filling method adopts fixed channel parameters and controls the filling time to achieve different metering filling. The metering of each filling head can be adjusted independently to achieve consistent filling and metering;

6. The whole machine is made of corrosion-resistant stainless steel, which is easy to clean and disinfect, and meets the national regulations and requirements on food machinery and food hygiene.

7. Imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation; can be connected with bottle unscrambler, capping machine, labeling machine into an assembly line, saving labor, high degree of automation, and can also be used alone .

8. Touch-operated color screen, which can display production status, operating procedures, filling methods, etc.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail