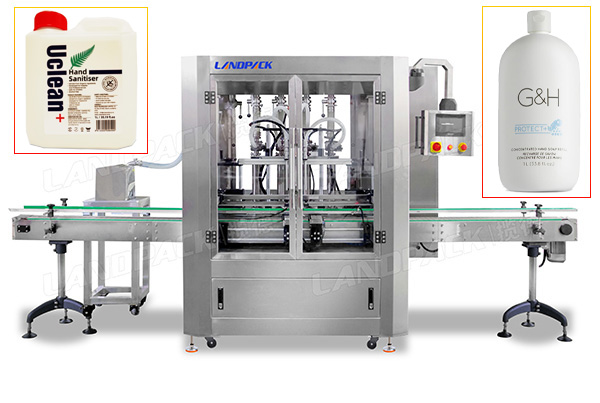

Automatic Hand Sanitizer Bottle Filling Machine With Capping And Sealing Line

Model: LFH-TJS-4

Application:

Automatic hand sanitizer bottle filling machine with capping and sealing line, it suitable for the filling of various liquids, such as hand sanitizer, alcohol, disinfectant, chili sauce, honey, tomato sauce, etc.

Advantage:

The product adopts advanced control technology, can set the filling amount and filling speed through the touch screen.

Application:

Automatic hand sanitizer bottle filling machine with capping and sealing line, it is suitable for filling liquids and pastes of various fluidity.

Examples:

Hand sanitizer, alcohol, Sauce, peanut butter, chocolate sauce, ketchup, shampoo, fruit juice, honey, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| Model | LFH-TJS-4 |

| Filling Range | 50-1000ml (customizable) |

| Filling Speed | 20-35 Bottle / min (refers to the range of 100-500ml) |

| Control Mode | PLC |

| Power Supply | 220V,50Hz-60Hz |

| Pressure | 0.6-1.0m³/min |

| Power | 8KW |

| Frame Material | 304#Stainless steel |

1.Imported PLC and 7-inch touch screen man-machine interface are adopted for production parametric control and simple operation;

2.The filling machine adopts special food hose without plasticizer, which is suitable for medicine, food and other industries;

3.The whole machine is made of corrosion-resistant stainless steel, which is convenient for cleaning and disinfection, and meets the national regulations and requirements on food machinery and food hygiene;

4.This line adopts 6-head servo piston filling machine, four-wheel rotating cap, automatic electromagnetic induction aluminum foil sealing machine etc;

5.The production line has stable operation, low noise, convenient maintenance, and fully meets the requirements of GMP certification. It is widely used in medicine, food, cosmetics and other industries;

6.The capping machine adopts the four-wheel clamping principle, which has the advantages of simple and reasonable structure, stable and reliable performance and high working efficiency, and solves the disadvantages of sliding and damaging the cover of the traditional capping machine;

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail