Automatic Fastener Screw Hardware Counting Packing Labeling Machine With 16 Vibration Devices

Model : LD-520

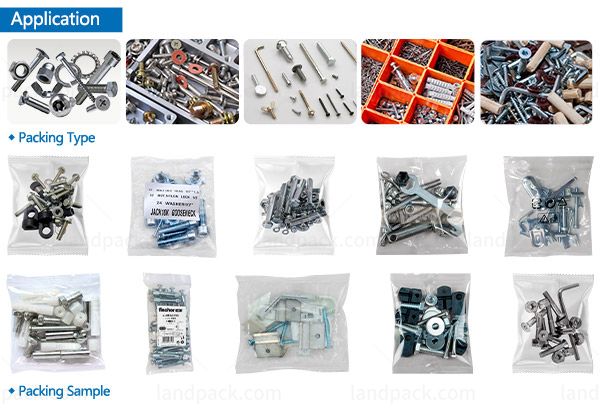

Application :

This machine is designed for automatic counting and packaging of a wide range of hardware and small components, including bolts, screws, nuts, fasteners, bearings, gaskets, hinges, nails, glass parts, plastic parts, toy accessories, furniture fittings, blind nuts, and more. Engineered for precision and efficiency, it optimizes the packaging process for various industrial applications.

Application :

This machine is designed for automatic counting and packaging of a wide range of hardware and small components, engineered for precision and efficiency, it optimizes the packaging process for various industrial applications.

Examples :

Bolts, screws, nuts, fasteners, bearings, gaskets, hinges, nails, glass parts, plastic parts, toy accessories, furniture fittings, blind nuts, and more.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Model | LD-420 | LD-520 | LD-720 | LD-900 |

Film width | Max.420mm | Max.520mm | Max.720mm | Max.900mm |

Bag length | 80-300mm | 80-350mm | 100-500mm | 100-600mm |

Bag width | 60-200mm | 100-250mm | 180-350mm | 260-430mm |

Film roll diameter | Max.320mm | Max.320mm | Max.320mm | 400mm |

Packaging rate | 5-60 bags/min | 5-60 bags/min | 5-55 bags/min | 5-20 bags/min |

Range of measurement | 150-1500ml | 2000ml | 4000ml | 1-25L |

Film thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

Power | 220V, 50/60Hz, 2kw | 220V, 50/60Hz, 3kw | 220V, 50/60Hz, 3kw | 220V, 50/60Hz, 4.5kw |

Machine size(L*W*H) | 1217*1015*1343mm | 1488*1080*1490mm | 1780*1350*2050mm | 2305*1685*2725mm |

Machine quality | About 650kg | About 680kg | About 750kg |

1. Intuitive PLC Control with Touch Screen Interface: Streamlines operations, providing a user-friendly experience and boosting operational efficiency.

2. Air Cylinder Mechanism for Stable Performance: Offers reliable performance with reduced mechanical wear, minimizing maintenance needs.

3. Real-Time Labeling Printer: Enables on-demand printing of expiry dates, batch numbers, and production information, ensuring traceability and compliance.

4. Precise Fiber Sensor for Product Counting: Accurately counts a variety of products, offering flexibility to meet diverse production requirements.

5. Enhanced Customization Options: Supports easy adjustments for different product sizes and packaging requirements, ensuring versatility across industries.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail