High Accuracy Hardware Furniture Fittings Counting Packing Machine With 7 Silence Vibration Disk

Model : LD-420H-7

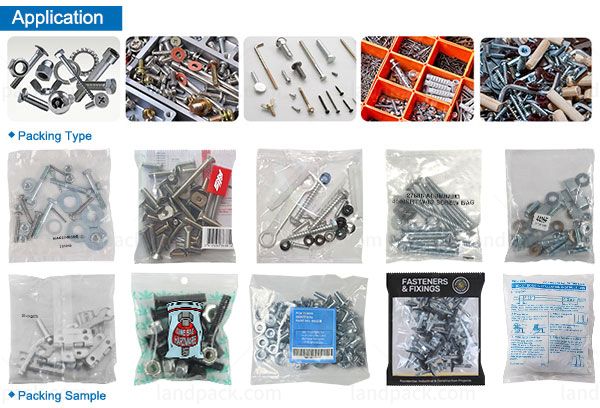

Application :

This machine is commonly used for packaging a variety of small, regularly shaped components, including fasteners, furniture parts, electronic appliance spare parts, plastic pipe fittings, clothing parts, toys, stationery, and more.

Application :

This counting packing machine is suitable for accurately counting and packaging various hardware and plastic parts. It ensures efficient and precise packaging for industrial applications.

Examples :

Hardware parts, nuts, bearings, bolts, screws, fasteners, and other plastic components.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples :

| Model | LD-420H-9 | LD-420H-10 | LD-420H-11 | LD-420H-12 |

| Speed | 10-30 bags/min | |||

| Counting Range | 1-10000pcs | |||

| Pouch size | 60 Main body L: 40-160 W: 20-110mm 388 Main body L: 40-200 W: 30-50mm 420 main body L: 50-300mm W: 80-200mm | |||

| Film Width | 60 Main body 220mm 388 Main body 320mm 420 Main body 420mm | |||

| Sealing type | Back sealing/Three sides sealing | |||

| Power | 6000W | 6500W | 7000W | 7500W |

| Voltage | 220V, 380V/50Hz/60Hz | |||

| Weight | 1100kg | 1200kg | 1300kg | 1400kg |

| Packing material | OPP/PE/PET | |||

| Air Consumption | 0.4m³/min, 0.6MPa | |||

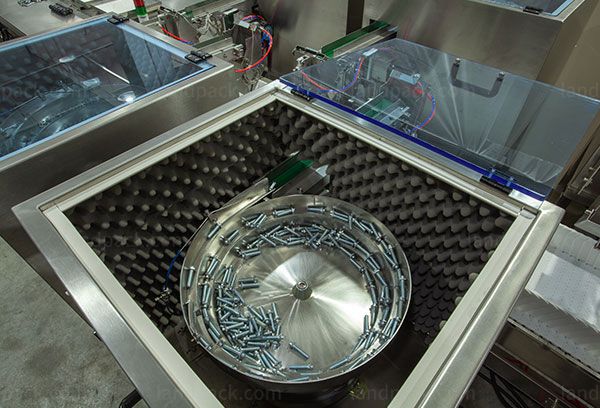

1. Noise Minimization Features: Each vibration plate is fitted with soundproof sponges and protective covers, effectively reducing noise levels during operation.

2. Automated Counting System: Capable of automatically counting up to 7 types of fasteners, replacing the need for manual labor and significantly increasing efficiency—equivalent to the work of 10 employees.

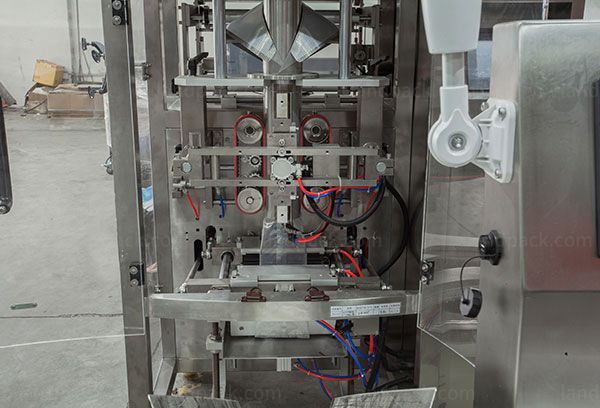

3. Adaptable Handling: Includes a manual delivery table for products that are not automatically fed, allowing for flexibility in handling small batches or irregular items.

4. Built-In Date Printer: Integrated with a printer to conveniently mark packaging with essential product details such as production dates and batch numbers.

5. Automated Quality Control: Equipped with a weight detection system that ensures only products meeting quality standards are packaged, automatically discarding any that are underweight.

6. User-Friendly Interface: Features an intuitive control panel that simplifies machine operation, enhancing ease of use and reducing training time for operators.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail