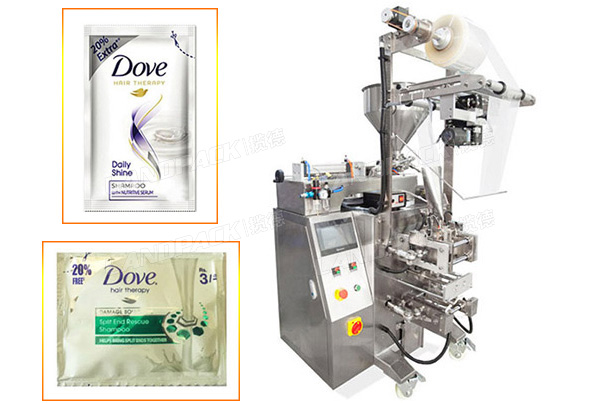

Automatic Multi Track Shampoo Stick Bag Pack Packaging Cartoning Machine

Model: LD560BY+LD200ZH

Application:

Widely applied for food, medicine, and chemical liquid products such as shampoo, juice, mouthwash, ketchup, flavoring, sauce, pasty, salad dressing, cream, body wash liquid, etc.

Advantage:

Automatic packaging and sealing without manual intervention, effectively reducing production and management costs.

Application:

Widely applied for food, medicine, and chemical liquid products such as shampoo, juice, mouthwash, ketchup, flavoring, sauce, pasty, salad dressing, cream, body wash liquid, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| MULTI-LANE STICK PACK SHAMPOO PACKAGING MACHINE | |

Model | LD560BY |

Lane number | 3-12 Lanes |

Filling Method | Piston pump; Peristaltic pump; Ceramic pump; Rotary pump |

Capacity | Max.50 cycles/min |

Sachet size | L: 50-180mm; W: 17-90mm |

Film width & Thickness | Max.560mm, 0.07-0.10mm |

Sealing type | Back sealing/ Stick bag |

Cutting type | 1.Straight cutting; 2.Zig zag cutting; 3.Round cutting; 4.Die-cut |

Air & Power | 0.8Mpa, 0.8m³/min,3.5kw |

Dimension & weight | 1385*918*2005mm,350kg |

| BOXING MACHINE | |

Model | LD200ZH |

Paper type | 250-400g/²(Boxes need come with pre-fold over) |

Capacity | 30-60 boxes/min |

Box type | Gusseted tongue type; Glue spray type |

Count way | Fixed number type; Numerable type; Manipulator counting |

Boxing way | Orderly type; Unorderly type |

Air & Power | 0.5-0.8Mpa 0.3m³/min;220V 50/60HZ 2.0KW |

Workflow | Box open - Bag packing - Check weigher - Counting - Boxing- Fold ears - Fold page - Gusseted tongue/Glue spray - Finish |

1. Automated Functions: This machine handles measuring, bag making, sealing, cutting, counting, and product conveyance automatically.

2. Safety and Concealment: Heat-generating and moving parts are discreetly hidden within a protective cover.

3. Hygienic Material Contact: The contact surfaces between the box and material are made of stainless steel, meeting the requirements for pharmaceutical and food production.

4. Mobility and Convenience: Equipped with casters, the machine is easy to handle and move.

5. Efficiency and Material Savings: Automatic alarms prevent material waste, ensuring efficient operation.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail