Fully Automatic Shampoo Bottle Filling And Capping Machine

Model: LFH-TJ-4

Application:

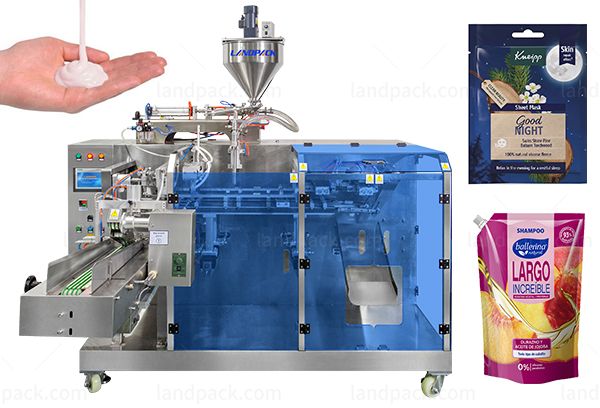

Fully automatic shampoo bottle filling and capping machine, It is suitable for the quantitative filling of various liquid such as shampoo, syrup, pesticide, mayonnaise, detergent, ketchup, mayonnaise, jam, paste, oil, cream, chili sauce, honey, etc.

Advantage:

The product adopts advanced general control technology, can set the filling amount and filling speed through the touch screen.

Application:

Fully automatic shampoo bottle filling and capping machine, it is suitable for filling liquids and pastes of various industries.

Examples:

Shampoo, sauce, peanut butter, chili sauce, detergent, syrup, honey, tomato sauce, olive oil, salad dressing, chocolate sauce, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

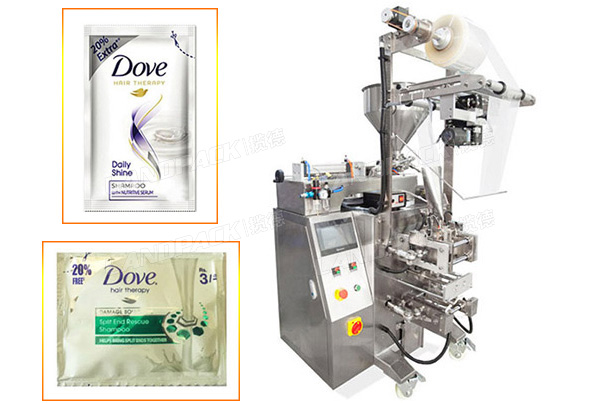

Packaging Sample:

| Model | LFH-TJ-4 |

| Filling Range | 50-1000ml (customizable) |

| Filling Speed | <15-25 bottles/min (refers to the range of 100-500ml) |

| Measurement Accuracy | ±1% |

| Control system | PLC |

| Total production line power | 5.5KW |

| Power supply | 220V、50Hz |

| Airconsumption | 0.6-0.8m³/min |

| Equipment material | 304 |

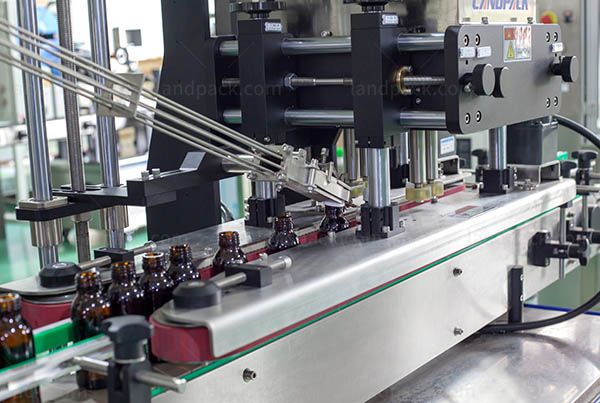

| Description of main packaging process | Unscramble bottles → Filling → Vibration plate upper cap → Four-wheel screw cap |

1. This production line adopts automation technology, imported PLC, imported inspection light eye, frequency converter and other electrical appliances, pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability, good stability, etc., and is well received by users;

2. This line uses automatic bottle feeding, 4-head servo piston filling machine, vibrating plate automatic capping, and four-wheel capping machine to form an automated production line;

3. The filling machine uses food-specific hoses and does not contain plasticizers, which is suitable for medicine, food and other industries;

4. The piston cylinder of the filling machine adopts grinding and wear-resistant metering cylinder, which can automatically compensate the piston seal for long life;

5. The whole machine is made of corrosion-resistant stainless steel, which is easy to clean and disinfect, and meets the national regulations and requirements on food machinery and food hygiene.

6. Different improvements can be made according to the different requirements of customers, and can be made into equipment that fully meets the needs of customers. The plexiglass cover of the whole machine is designed to prevent impurities from entering the filling material, which is safe and hygienic.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail