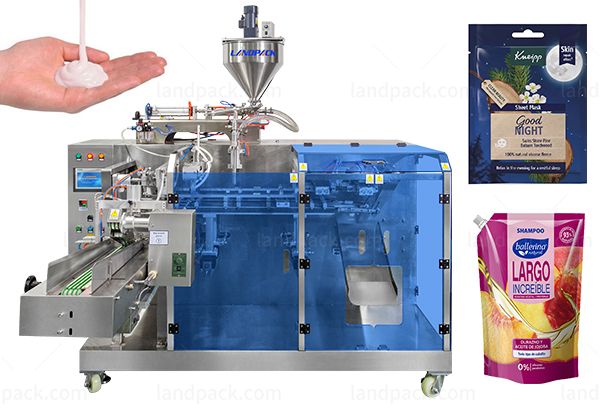

High Efficiency Shampoo Horizontal Premade Pouch Doypack Packing Machine

Model: GP-210L

Advantage:

Using high-quality mechanical and electronic components, the operation is stable and reliable, and the failure rate is low.

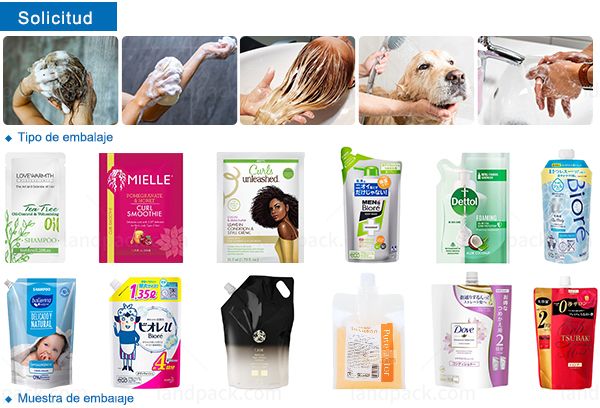

Application:

Suitable for shampoo, detergent, syrup, honey, milk, oil, ketchup, paste, sauce, etc.

Application:

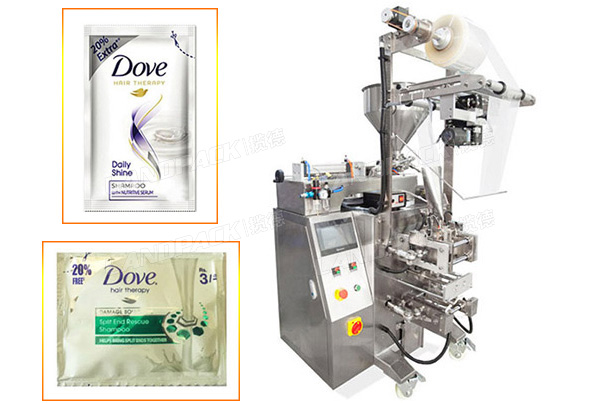

High efficiency shampoo horizontal premade pouch doypack packing machine(GP-210L), it can automatically complete a series of operations such as bag feeding, bag opening, measuring, sealing, and cutting, which greatly improves packaging efficiency and reduces labor costs.

Examples:

Shampoo, detergent, syrup, honey, milk, oil, ketchup, paste, sauce, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

1.Different machine models available to meet a wide range premade bag size.

2.Customized main machine structure for various kinds of bag shape. Like doypack zipper bag, 4 side seal bag, stand up bag and irregular bag, ect.

3.With upgrade PLC control system, easy for operation on touch screen of parameter setting.

4.Machine machine can equipment with different metering system like weigher, liquid pump, auger filler, bucket chain for different kinds of product filling and packing in premade bag.

5.The liquid horizontal bagging machine enables high-speed packaging and is suitable for high-volume production.

6.It can automatically complete a series of operations such as bag feeding, bag opening, measuring, sealing, and cutting, which greatly improves packaging efficiency and reduces labor costs.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail