Automatic Spice Powder Horizontal Pouch Doypack Packing Machine

Model: GP-260D

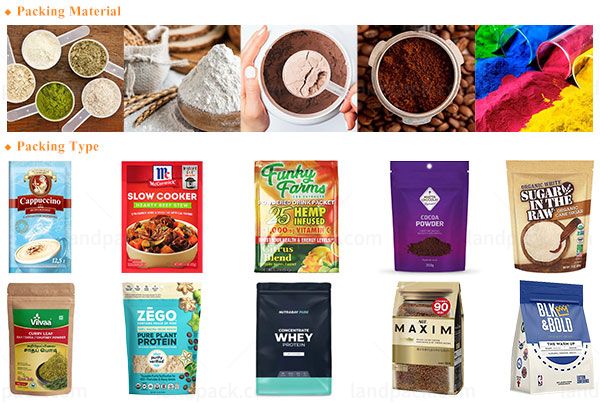

Application:

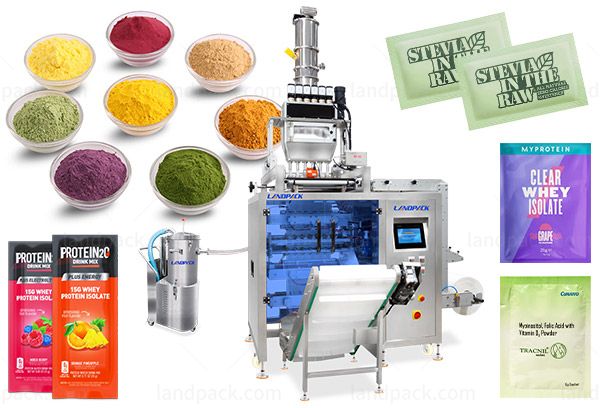

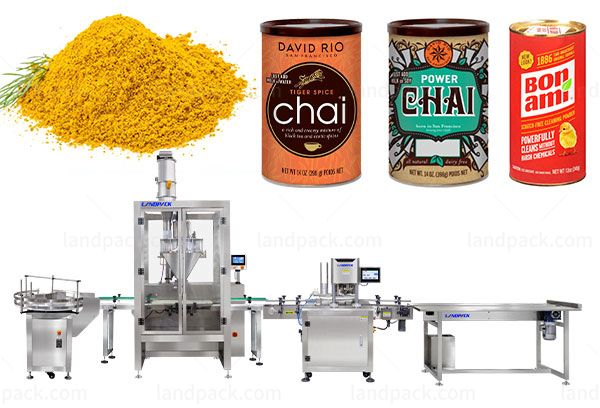

It suitable for packaging of materials requiring high accuracy of measurement or careful handling, such as spice powder, milk powder, coffee powder, tea powder, wheat flour, detergent powder, coconut powder, pesticide powder, medical powder, etc.

Application:

Automatic spice powder horizontal pouch doypack packing machine, it can automatically complete the measurement, packaging and sealing of materials to improve production efficiency.

Sutable Pouch:

Doypack, box pouch, zipper pouch, stand up pouch, stand up pouch with hole, kraft paper bag, side gusset bag etc.

Examples:

Spice powder, milk powder, coffee powder, tea powder, wheat flour, detergent powder, coconut powder, pesticide powder, medical powder, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examples:

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

1.This is a fully-automatic packing machine with Multi-function which can be integrated with various filling systems.

2.High capacity auger feeding machine, save labr cost

3.Servo motor to control and high speed to work.

4.Automatic alarming function and stop when the inadequate air pressure.

5. High precision horizontal bag feeding device, speed adjustable)

6.Famous brand components, ensure the quality and durability of machine.

7. Open the zipper efficiently and accurately;

8. Heavy weight prowder,beautiful packaging, accurate measurement

9. Vacuum cleaning to keep the bag mouth clean;

10.smooth performance and low noise, perfect package appearance with enough film storage, Sensible safety device and no pollution during production to get Friendly working environment.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail