Automatic Spice Powder Weighing Doypack Premade Pouch Packing Machine

Model : LDSP-210

Application :

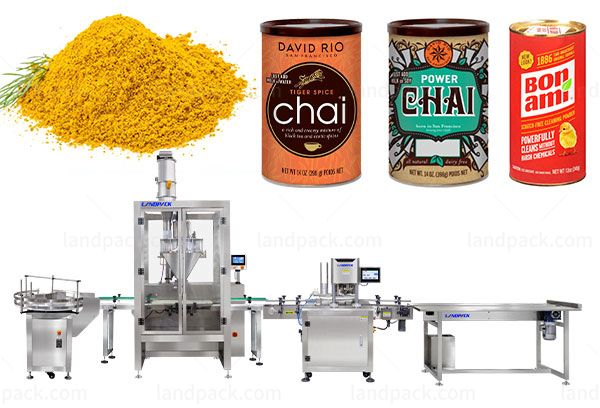

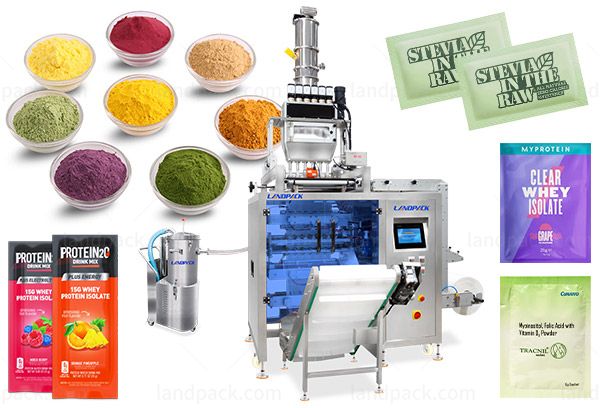

This premade pouch filling and sealing machine is designed to efficiently package powdered products, including spice powder, milk powder, coconut flour, protein powder, coffee powder, potato flour, and more. It ensures precise filling and sealing, making it perfect for high-quality packaging in a variety of industries.

Application :

This premade pouch filling and sealing machine is designed to efficiently package powdered products, it ensures precise filling and sealing, making it perfect for high-quality packaging in a variety of industries.

Examples :

Spice powder, milk powder, protein powder, coffee powder, coconut flour, potato flour, and more.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample :

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4-side sealing bag, stand-up bag, handbag, spout bag, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45 bags/min(speed is determined by the product filling quantity) | 25-50 bags/min(speed is determined by the product filling quantity) | 20-50 bags/min (speed is determined by the product filling quantity) | 20-50 bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

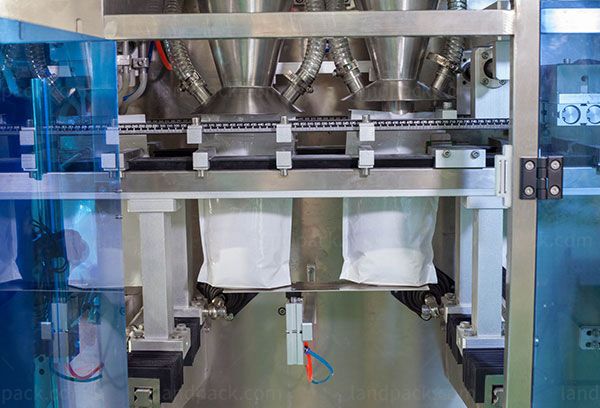

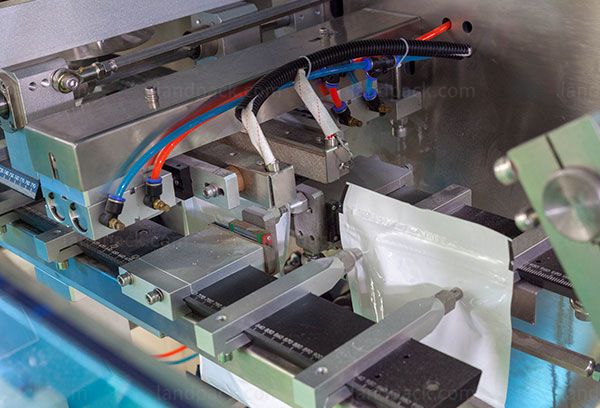

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | |||

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | |

| Collocation | Screw metering, screw elevator | |||

1. Precise Weighing Mechanism: Features a specialized weigher with a distributor designed to handle small granules with high accuracy and efficiency.

2. Dual Function Filling System: Combines a multi-head weigher with a horizontal screw measuring device, allowing both granules and powder to be accurately filled into the same bag for a perfect blend.

3. Dust-Free Operation: Equipped with a dedicated dust collection system on both the weigher cover and filling hopper, ensuring a cleaner and more controlled working environment.

4. Versatile Filling Capabilities: This system is adaptable for various granular and powdered products, providing high flexibility for different product types and packaging requirements.

5. Improved Packaging Precision: The dual system ensures optimal packaging for both powdered and granular materials, delivering consistent fill weights for a variety of product types.

6. Efficient and Clean Process: The machine's design minimizes material spillage and product loss, promoting a more efficient production line while keeping the workspace dust-free.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail