Spice Packing Machine | Multi Lane Sachet Filling Sealing Machine With Vacuum Feeder

Model : LDFS-960D-6

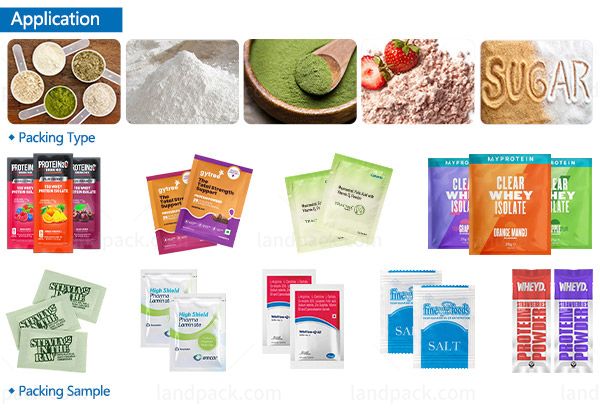

Application :

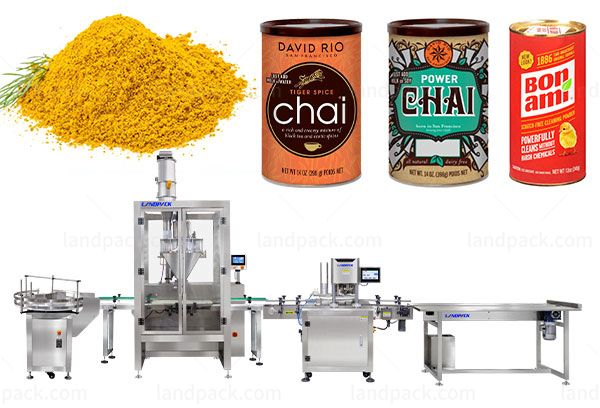

This multi lanes powder sachet packing machine can make bags, measure, fill, seal, and make easy tearing notches. Suitable for food, cosmetics, and medicine packing such as spice powder, masala, turmeric, seasoning, flour, pepper, washing powder, and all kinds of powder, etc.

Application :

This multi lanes powder sachet packing machine can make bags, measure, fill, seal, and make easy tearing notches. Suitable for food, cosmetics, and medicine packing .

Examples :

Spice powder, masala, turmeric, seasoning, flour, pepper, washing powder, and all kinds of powder, etc.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers :

Model | LDFS-480D | LDFS-720D | LDFS-960D | LDFS-1200D |

Track Number | 4-6 Track | 4-8 Track | 4-10 Track | 4-12 Track |

Filling Method | Auger filling by servo motor | |||

Capacity | 20-40 bags/cut | |||

Sachet Size | L:45--120mm;W:50-60mm | L:45--120mm;W:50-90mm | L:45--120mm;W:50-120mm | L:45--120mm;W:50-150mm |

Film Width&Thinckness | Max.480mm;0.07-0.1mm | Max.720mm;0.07-0.1mm | Max.960mm;0.07-0.1mm | Max.1200mm;0.07-0.1mm |

Sealing Ttype | 4side sealing | |||

Cutting Type | 1.Straight cutting 2.Zig zag cutting 3.Continous cutting | |||

Air&Power | 0.8MPA 0.8m³/min;2.8kw | 0.8MPA 0.8m³/min 4.1kw | 0.8MPA 0.8m³/min 5.5kw | 0.8MPA 0.8m³/min 6.5kw |

| DIM&WT | 950*1470*1750mm 300kg | 1153*1654*1750mm 400kg | 1415*1686*2130mm 500kg | 2220*2210*2600mm 800kg |

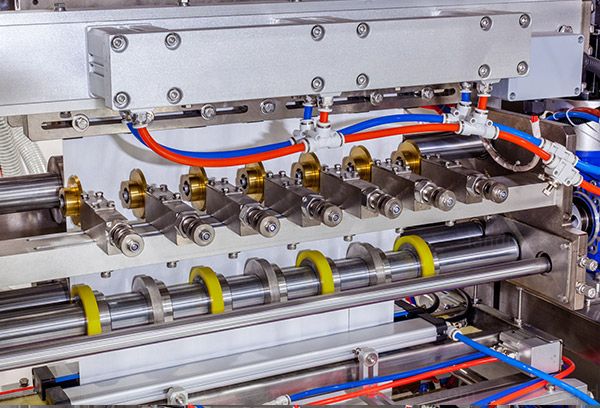

1.The machine precisely measures small quantities down to 1 gram with automatic reloading capability for micro-dosing applications.

2.Delivers exceptional filling accuracy with a tolerance of just 0.03-0.05 grams for ultra-precise powder measurement.

3.Features a high-precision drawer-style measuring cup system that ensures consistent dosing performance.

4.Equipped with premium-brand electrical and pneumatic components for reliable operation and extended service life.

5.Designed with separated electrical circuits for easy maintenance identification and reduced operational noise levels.

6.Maintains consistent measurement precision within ±1 gram tolerance across all production cycles.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail