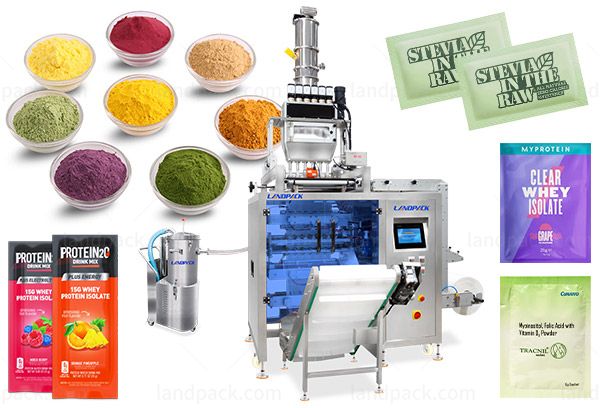

Multifunction Spice Powder Horizontal Premade Pouch Packing Mahcine Automatic Doypack Machine

Model : LDSP-210D+L

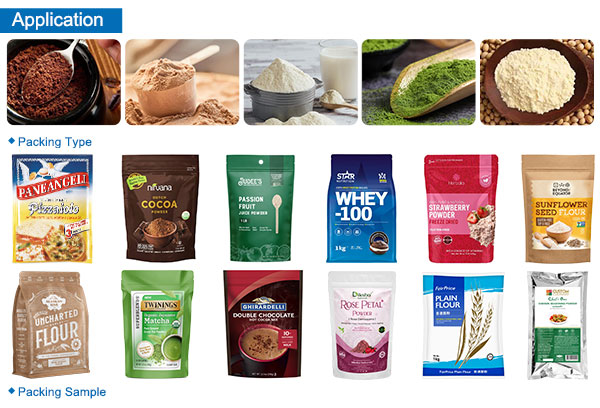

Application :

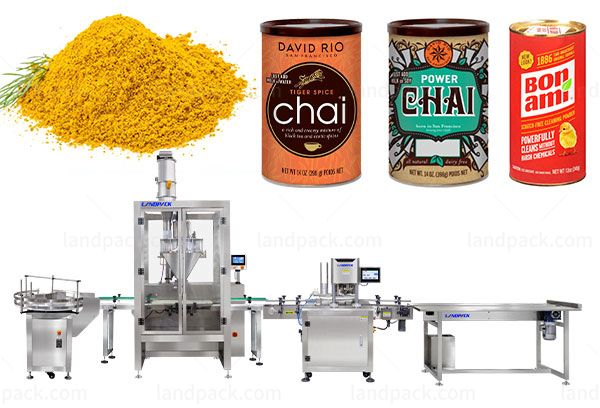

A versatile packaging machine designed for both powder products (seasoning powder, protein powder, milk powder, tea powder, spices, coffee, etc.) and liquid products ( jam, milk, oil, ketchup, honey, sauce, juice, etc.), offering efficient and flexible solutions for diverse industries.

Application :

A versatile packaging machine designed for both powder products, offering efficient and flexible solutions for diverse industries.

Examples :

Spices, seasoning powder, protein powder, milk powder, tea powder, coffee powder, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4-side sealing bag, stand-up bag, handbag, spout bag, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45 bags/min (speed is determined by the product filling quantity) | 25-50 bags/min (speed is determined by the product filling quantity) | 20-50 bags/min (speed is determined by the product filling quantity) | 20-50 bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

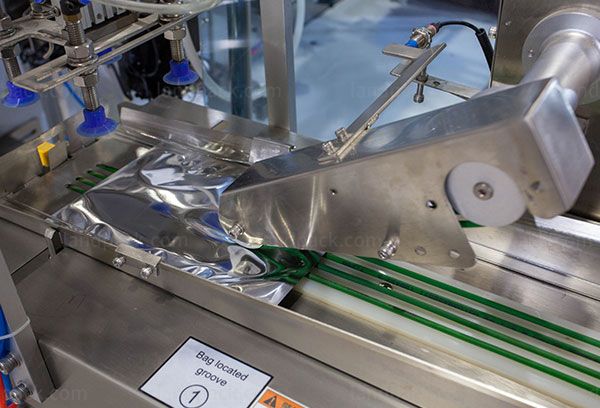

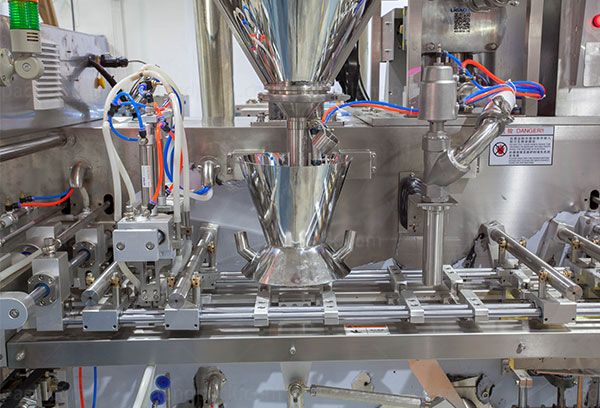

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | |||

| Dimensions | 1750*1285*1360mm (L*W*H) | 2140*1366*1360mm (L*W*H) | 2140*1366*1360mm (L*W*H) | |

| Collocation | Screw metering, screw elevator | |||

1. Dual-Purpose Design: This innovative machine is equipped with a versatile filling system that can handle both powdered and liquid substances. The transition between materials is seamlessly managed through an intuitive touchscreen interface, offering flexibility in production.

2. Enhanced Stability Bag Feeder: The horizontal bag feeder system is engineered to provide superior stability during the bag feeding process. This feature ensures a smooth and efficient operation, reducing the risk of errors and downtime.

3. Comprehensive Bag Opening Mechanism: The upper and lower bag opening devices are designed to ensure that every bag is opened completely and accurately. This comprehensive system guarantees that the filling process is successful and precise, every time.

4. Adjustable Bag Compatibility: The machine is built with flexibility in mind, allowing it to accommodate a wide range of bag sizes. This adaptability meets the varying demands of different packaging requirements, making it a valuable asset in diverse production environments.

5. Intuitive Touch Screen Interface: The user-friendly touchscreen simplifies the operation process, making it easy for operators to manage the machine. This interface not only enhances production efficiency but also reduces the learning curve for new users.

6. Consistently Reliable Performance: The machine is built for reliability, ensuring that every filling operation is stable and accurate. This consistent performance is crucial for maintaining uniform packaging quality across all products, which is essential for consumer satisfaction and brand reputation.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail