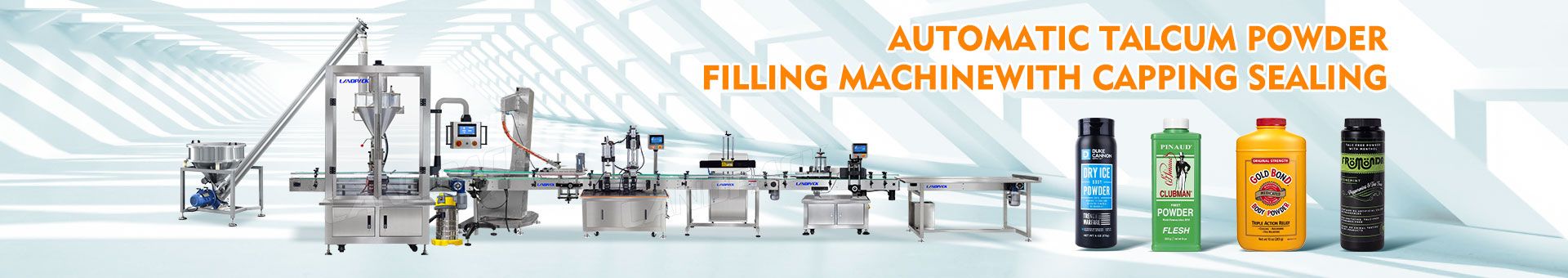

Automatic Baby Talcum Powder 3 Heads Filling Capping Machine Production Line

Model : LDPAF-01

Application :

This powder filling line is primarily designed for filling a wide range of powder materials into bottles with precision and efficiency. It is ideal for products such as talcum powder, baby powder, milk powder, coffee powder, protein powder, grain powder, tea powder, chili powder, spice powder, and more, ensuring consistent, high-quality packaging for various industries.

Application :

This powder filling line is primarily designed for filling a wide range of powder materials into bottles with precision and efficiency, ensuring consistent, high-quality packaging for various industries.

Examples :

Talcum powder, baby powder, milk powder, coffee powder, protein powder, grain powder, tea powder, chili powder, spice powder, and more.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample :

| Powder Mixer | |

| Part name | Powder mixer 200L |

| Material | SS304 |

| Composition | The horizontal ribbon mixer consists of a U-shaped container, ribbon mixing blades, and transmission parts |

| Feature | Horizontal cylinder, U-shaped mixer cylinder |

| Full volume | 250L |

| Effective capacity | 200L |

| Rotating speed | 46rpm |

| Power supply | 3P AC208-415V 50/60Hz |

| 3 Heads powder filling machine | |

| Filling heads | Three screws dosing device |

| Material of Nozzle | SS304, meets GMP production requirements |

| Material of machine | SS304, 1.5mm thickness |

| Filling Speed | 35-40 bottles/minute. Can be adjusted to prevent bottle overflow |

| Filling form | Three screw filler |

| Filling sensor | Included, No bottle no filling |

| Control method | PLC+Touch screen |

| Air consumption | 0.6MPa |

| Dust removal device | Yes |

| Cap Pressing Machine | |

| Item | Press capping machine |

| Capping Speed | 50-60 bottles/min |

| Bottle and cap size | Can be customized and adjustable |

| Air pressure(mpa) | 0.3-0.5 |

| Voltage | 220V/50HZ |

| Weight | 100 kgs |

1.The solution seamlessly integrates all processes, including feeding, weighing, filling, servo capping, sealing, and labeling, for a fully automated production line.

2.Equipped with a servo-driven capping machine that allows for precise torque control, ensuring secure and reliable seals on every bottle.

3.Delivers rapid performance while maintaining stability throughout the entire packaging process, enhancing overall production efficiency.

4.Specifications can be quickly adjusted, and filling volumes can be modified directly via the touchscreen interface, offering easy customization.

5.A three-head powder filling machine featuring a servo-controlled auger system, ensuring exceptional accuracy in filling powders and granular materials.

6.The vacuum feeder efficiently transports powder to the filling machine, reducing the required floor space while maintaining smooth material handling.

7.Equipped with an advanced photoelectric sensor, the system ensures that the filling, capping, and labeling processes are only triggered when bottles are properly positioned.

8.The system is designed for easy changeover between different bottle sizes and product types, minimizing downtime and optimizing production.

Get Price & More Detail